views

Planning

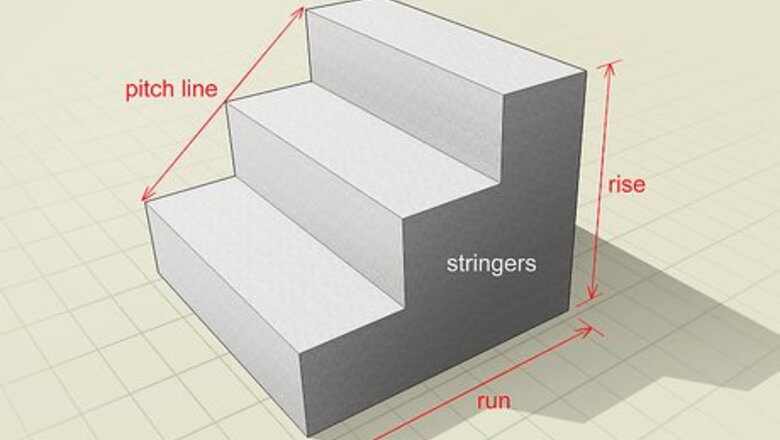

Equip yourself with a stair-building vocabulary. Each step consists of 2 main parts: a riser, which is the vertical part of the step, and the tread, which is the part you step on. Other important terms to know when building your stairs include: The pitch line, an imaginary line that runs from the lip of the bottom stair to the lip of the topmost step. The “pitch” of the stairs is the angle between the base of the stairs and the pitch line. The rise, which is the total height of your staircase from its base to the topmost step. The run of your stairs, which is the depth of your stair measured from the front of your staircase to its back. The stringers of your stairs are the side supports to either side of each step. The measurements for your stringers will be used in the creation of your concrete forms.

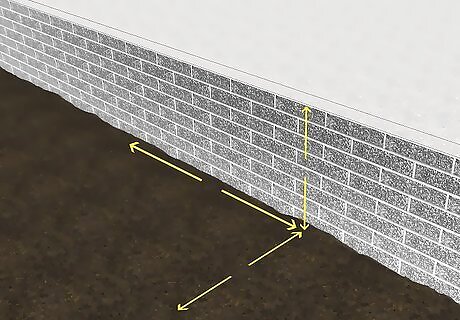

Measure the dimensions for your stairs. First, you'll need to find the total rise of your stairs, which can be found by measuring the total height from the planned base to the higher level/floor you are building up to. Then: Measure the run of the steps by finding the distance between the frontmost and backmost parts of the stair. Find the width of your stairs by measuring the distance between the leftmost and rightmost bounds of your planned steps.

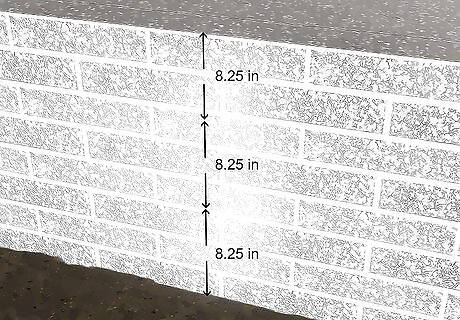

Calculate the number of stairs you will need. You can do this by finding the rise (total height from the bottom level to the top level) of your stairs and dividing that number by the riser height (the height of each step). Standard risers are between 6 to 8 in (15 to 20 cm). The building code in some states sets the maximum riser height at 8.25" (21 cm), but you should be sure to check your local building code to prevent building stairs that violate state code or local ordinances. If this number comes out as a decimal, you must round up to the next whole number. If your stairs are built so the topmost tread is a step below the level/floor you are building up to, the number of treads you need will be 1 less than the number of risers. Otherwise, you will need an equal number of treads and risers. There are many online sites that offer simple step calculators to simplify this process. You should be able to find these through a general Internet search for a "stair calculator." These calculators will help you determine the exact specifications of your steps, including the number of treads, the height of each riser, the stringer length, the pitch line, and so on.

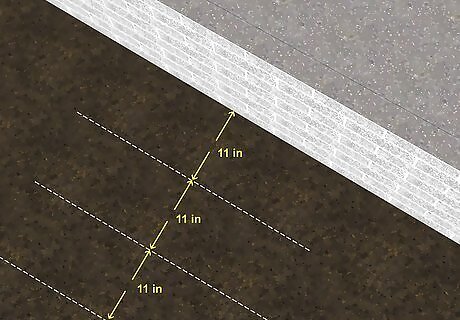

Determine the height and depth of your tread. The depth of each tread (the top surface of the step) is a little more flexible, but each should be at least 11 inches (27.9 cm) to accommodate both large and small feet.

Find the height of your risers. Divide the total rise (height) of the entire staircase by the number of risers. Generally, you should round the riser height of your steps to the nearest 1/16 inch (1.6 mm).

Find the length of your stringers. The stringers of your stairs will form the angled, side parts of your form on either side of your stair. To find the length of your stringers, multiply your total rise by itself. Then multiply the total run by itself. After that you'll need to: Add the rise multiplied by itself and the run multiplied by itself together, and then take the square root of that number. Finally, find the angle of your stringers by taking inverse sine (sin) of your total rise divided by the length of your stringers. It may be easiest to use a calculator, phone, or online calculator to find the length and angle of your stringers. The square root symbol will look like a checkmark or a checkmark with a horizontal top (√).

Plan for handrails if you need them. You may have to install brackets in the concrete when you pour, so determine if handrails are a necessity for your stairs. If the stairs are next to a wall, you can always attach a handrail to that.

Groundwork

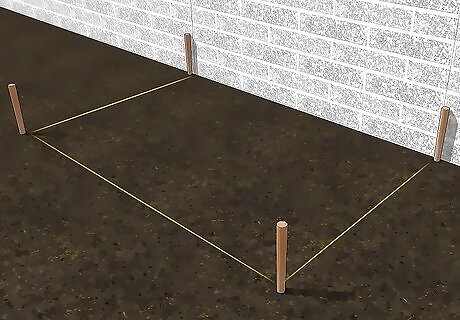

Stake out the base of your steps. Now that you know the general dimensions of your steps, you can stake out the area where you will be building your steps. Hammer a wooden stake into the ground at each corner of the base of your stairs. Measure from corner to corner to ensure that your layout is properly squared up and the dimensions are correct. To make sure that your stakes are evenly lined up, run a length of string between the stakes around the perimeter and use the string to verify your stakes are aligned properly. Not running a line between your stakes to keep alignment can lead to more work on your part. In the worst-case scenario, a poorly aligned perimeter can result in a slanted/angled finished product.

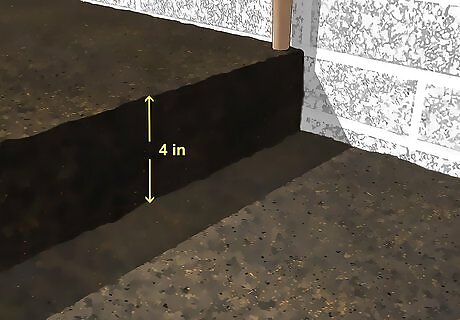

Excavate the area where your steps will be poured. You'll need to use a shovel to dig 4-8" (10.2-20.3 cm) below the ground level of the base of your stairs. Dig within the boundary of the string you've set up to prevent digging any more than you have to. This excavation is intended to clear away rocks, trees, grass, shrubs, and anything else that might interfere with your concrete pouring. You'll also have to lay a sub-base upon which the concrete will rest. Since your sub-base should be at least 4-8" (10.2-20.3 cm) thick, you'll need to dig down at least this far or the rise of your first step will be larger than you plan.

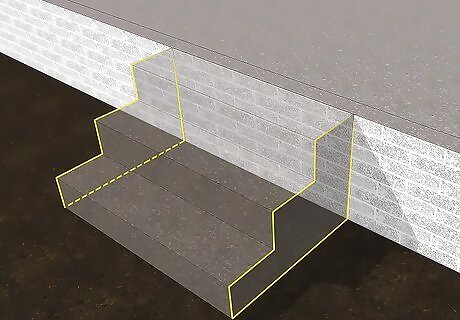

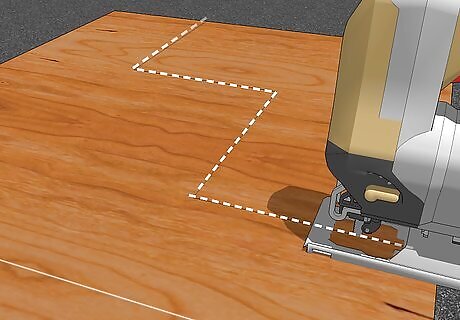

Cut the pieces for your form. Using the dimensions you've taken for your staircase, cut pieces of scrap wood or low-grade lumber so you have a board for the rise for each step and two boards for the stringers (one for each side of your stair form). Use 2 in × 6 in (5.1 cm × 15.2 cm), 2 in × 8 in (5.1 cm × 20.3 cm), or plywood that's ⁄4 in (19 mm) thick. Your form should exclude the top and bottom of the entire stair. The ground-oriented side of your stringer forms should be cut to meet the pitch line (angle) of your stair, and the top should be cut in a zigzag fashion to follow the rise and depth of each tread (step). If you are pouring concrete steps that form a right angle (L-shape), your stringer forms will not need to be cut on an angle. In this case, your stringer will follow the entire run and rise of your stairs. You should shave a slight angle into the bottom of each rise form board, excluding the bottom riser form board. This way, when you pour your concrete, you'll be able to easily smooth the area in the corners of each step.

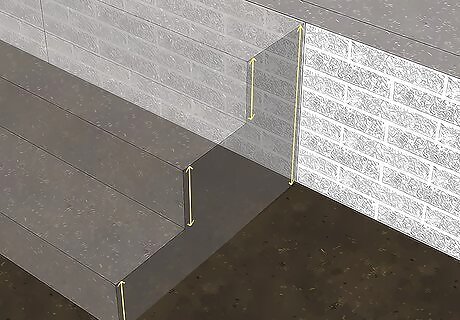

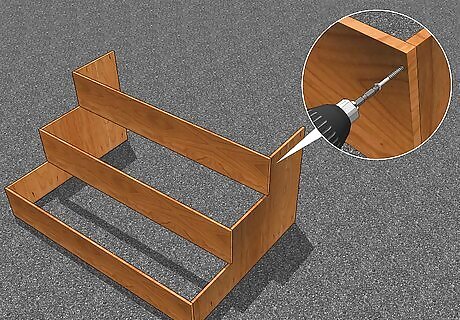

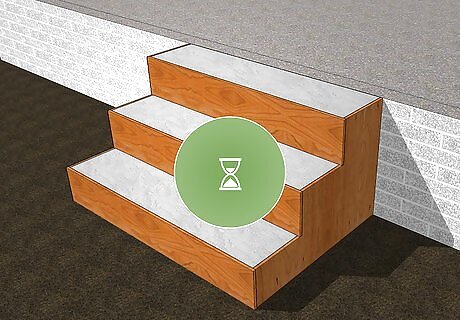

Assemble your concrete form. Use screws and a power drill to attach each riser from the board to your stringers. You can do this by laying each stringer form so the even, bottom side of each stringer is flat on the ground and the zigzag side of the stringer is oriented with its points facing up. Screw 2 in × 4 in (5.1 cm × 10.2 cm) planks into the form and fasten them to the ground with wooden stakes to prevent the form from bowing out. Space your stringers to be approximately the planned width of your stairs apart. Then you can lay the riser form boards along the zigzags of the stringer that matches the upward rise of each step. Now you should be able to easily use your power drill to attach each riser form board to the stringer form boards. If your stairs form a right angle (L-shape), you should be able to lean them against a sturdy object base down so each stringer form is oriented like a normal stair. You may have to place a board between the stringers to stabilize them until you screw your first riser form board into place. Be sure there are no gaps in your form and that the boards line up evenly. Any gaps can lead to concrete leaking through your form, and unevenness will result in uneven steps. When you look at your form from the side, it should look like finished steps.

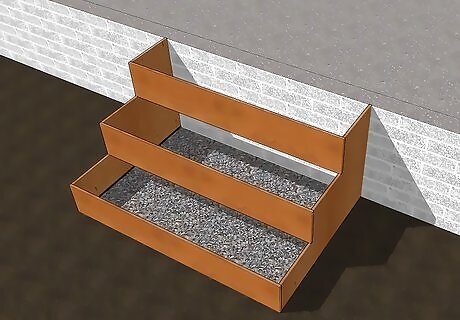

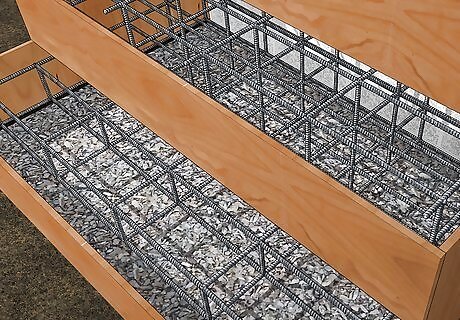

Lay your subbase. Your concrete steps will lie upon a sub-base of granular fill, like open-grade stone, which will protect your poured concrete steps from shifts in the earth or deterioration. You'll need between 4-8" (10.2-20.3 cm) of fill for your subbase. After placing your subbase, you'll need to tamp it down until it is packed extremely firm, level, and stable. Use a long flat board and a level to check the levelness of your subbase. Smaller projects can likely be done with a hand tamper, which is essentially a heavy, flat metal plate attached to a wooden handle. Larger projects might require you to use a plate compactor machine. Failing to lay a sturdy subbase can result in cracking, deterioration, or structural failure in your concrete steps. Your concrete's strength depends on a solid sub-base. You may want to lay a thick gauge wire mesh on top of your subbase to reinforce the concrete you'll be pouring. The idea is, even if your concrete cracks, the mesh will hold it in place so the integrity of your stairs is maintained. If you live in a colder climate, you can apply a layer of Styrofoam 2 inches (5.1 cm) deep before adding gravel so frost doesn't freeze underneath your steps and damage them.

Place your form. Fit your stair form into place over the sub-base, slotting it into the gap created by the ground level/floor and the level you are building your stairs up to. Once your form is in place, use a level to check that it isn't sloping in one direction or the other. You may have to add a little fill to either or both sides of your form to ensure it is level. You may want to give your form a very slight downhill angle. This way, when it rains, the water will run off your steps.

Build a rebar cage into your form. A rebar cage will provide additional reinforcement and help your stairs last longer. Use rebar that is at least 3/8 of an inch (.95 cm) in diameter and connect it with wire ties. The top of the rebar cage should be at least 2 inches (5 cm) under the height of the finished steps. Use bolt cutters or an angle grinder to cut the rebar pieces to the right length. You will need a pigtail twister to secure the wire ties.

Pouring and Finishing

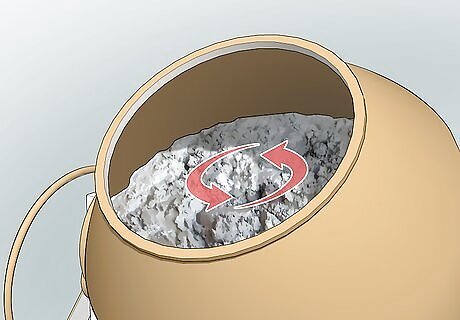

Mix your concrete. For a project as large as a staircase, you will likely need to rent a small cement mixer. Follow the directions on your bagged concrete mix to determine how much water you need to add. Smaller projects, like building a single step, might be possible without a cement mixer. You could mix your concrete by hand in a wheelbarrow. Another alternative is to create a mixing box (also called a mortar box) by using scrap/low-grade wood to create a makeshift reservoir where you can mix your concrete. Add colorant to your concrete before mixing it to permanently change the color.

Pour the concrete. Transfer the concrete into your form with a shovel, wheelbarrow, or (for larger projects) the funnel that came with your cement mixer. If you are using a wheelbarrow, you might construct an earthen ramp so you can wheel your cement up to the lip of the form and tip in the concrete.

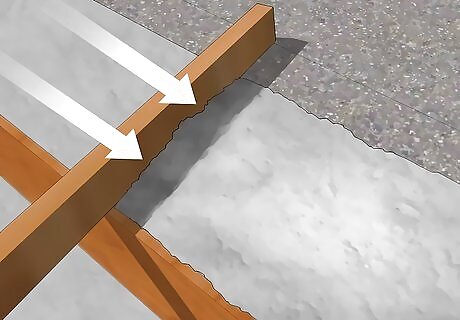

Screed (flatten) the surface of your concrete. Lay a screeding tool, like a long trowel or long wooden plank, flat along the top parts of your form and, working from uphill to downhill, work your tool along the form to flatten and smooth the concrete. Once you are finished screeding, your concrete should start looking more like the finished product. If you use a wooden plank or board, it should be as straight as possible and free of warping and other irregularities. These can create gouges or leave the surface of your concrete uneven.

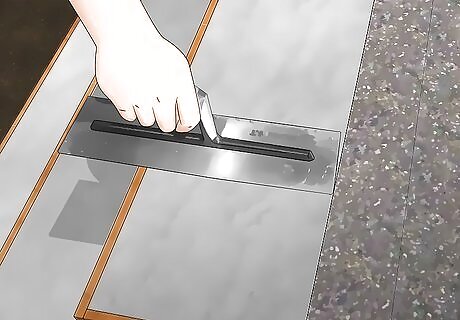

Float your concrete. Floating involves pressing a flat surface along the top of the concrete to cause the "cream" (the gravel-free part of the concrete) to come to the surface. A bull float tool is ideal for this process, though it might not be necessary for smaller projects. Smaller projects might only require the use of a handheld magnesium float. These kind of floats are extremely durable and are designed to slide across the surface of your still-liquid concrete easily. To use a bull float, push it away from you across the top of the concrete while keeping the back end of the float slightly elevated, then pull the float back towards yourself, keeping the front end slightly elevated. Float the entire surface of your concrete thoroughly. If you have used a bull float, you should use a handheld magnesium float to go over the surface once again when finished. Use long, sweeping motions for best results. At this point, it is not uncommon to see water bleed to the surface of the concrete.

Brush your concrete for improved traction. Drag a stiff-bristled push broom across the surface of your concrete to create fine grooves in the surface. Smooth concrete can be very slippery, which can be especially dangerous for concrete steps. Use light pressure when doing this; grooves that are too deep will cause water to puddle on the concrete and could compromise its integrity. If you notice clumps of cement forming on your broom, this is generally a sign that you are adding traction too soon. Smooth the concrete once more with your handheld magnesium floater, and wait until later to brush your surface. Wait to do this until the concrete has dried enough that you no longer see water seeping (or “bleeding”) out onto the surface. Otherwise, brushing will result in grooves that are too deep.

Allow your concrete to cure. You should always follow the directions of the supplies you use, especially since different kinds of concrete will have different specifications. Generally, concrete takes 28 days to fully cure. You can improve the curing process by applying a concrete sealer after pouring the concrete. Follow the directions on your sealer for the best results. You should be able to remove your forms after a single day. Carefully remove your screws and take apart your form. After a few days, your concrete will be strong enough to walk on, though not fully cured. Enjoy your new concrete steps!

Comments

0 comment