views

Cutting and Shaping the Glass

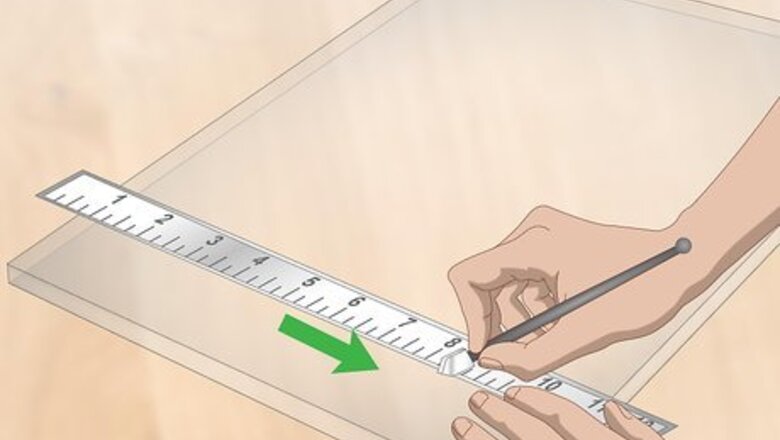

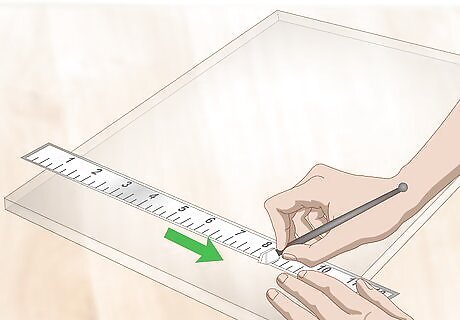

Cut the glass into the desired shape first. You have to cut and shape the glass before the glass is tempered. You will weaken or break the glass if you attempt to cut or reshape it in any way after tempering.Warning: Always wear safety glasses and a face mask that covers your mouth and nose when you are cutting and shaping glass to prevent you from breathing any glass dust in. Tempered glass is much harder than regular glass. However, if you cut, drill, or otherwise modify it after tempering, then it is highly likely that it will shatter into small pieces because it is more brittle than regular glass. Even if it doesn’t break, the glass will be compromised and will not be as strong as intended.

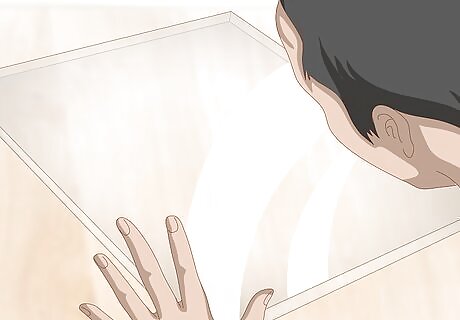

Inspect the glass for imperfections like cracks and bubbles. Look closely to make sure that there are no cracks or other imperfections in the glass after you cut it to size. Such imperfections can make the glass break during tempering, so do not try to temper glass with any cracks or bubbles. It’s important to do this after cutting the glass, in case any cracks or other damages were caused while cutting the glass.

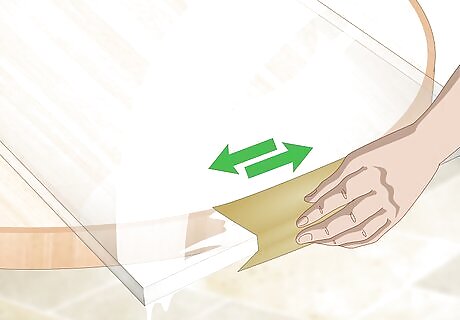

Sand the edges of the glass with wet sandpaper until they are smooth. Use a medium-coarse sandpaper like 80-grit sandpaper. Wet the sandpaper to keep glass dust from flying up in the air, and sand along the edges until the sharp edges are gone so that they aren’t dangerous. You can sand the edges by hand, with an electric sander, or with a rotary tool like a Dremel tool.

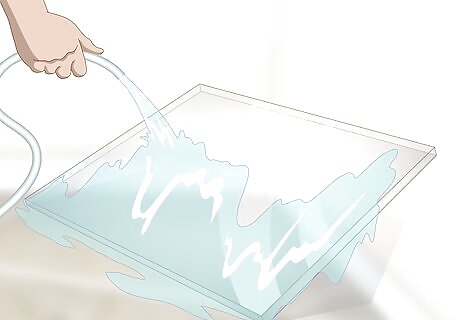

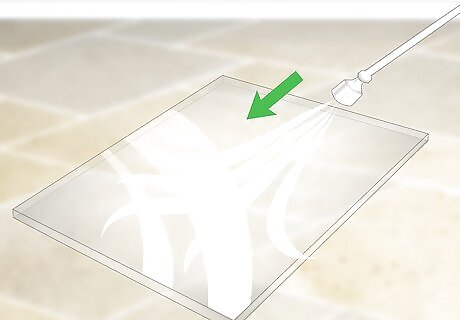

Wash the glass to remove dust from sanding and any dirt. Small grains of glass and dirt can interfere with the tempering process. Make sure to wash the glass thoroughly to remove any traces of loose materials from it. You can just use regular, cool water. There is no need for any special cleaners.

Heating and Cooling the Glass

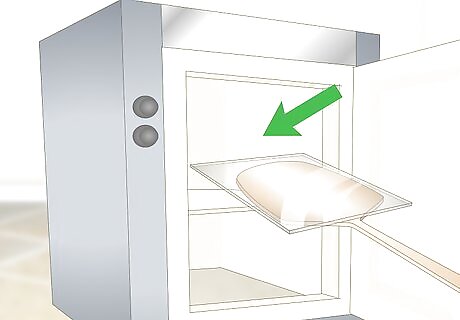

Place the glass in a heated tempering oven or kiln with tongs or a paddle. The temperature needs to be at least 600 °C (1,112 °F) in order to temper the glass, so make sure the oven is at least this hot before you put the glass in. The industry standard for tempering glass is 620 °C (1,148 °F). You can use any type of oven or kiln to temper glass, as long as the temperatures can get high enough, although a tempering oven is ideal.

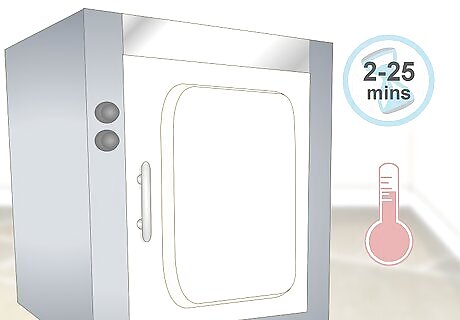

Heat the glass for 2-25 minutes to temper it. Glass will take between 2 and 25 minutes to temper depending on the thickness, temperature of the oven, and other factors. Heat it for a full 25 minutes at above 600 °F (316 °C) to be sure you temper it. In a glass tempering facility, you will be able to be more precise with the times because of the special ovens they have. However, if you are tempering glass in less-scientific conditions, then you will have to experiment to learn exactly how long it takes to temper different thicknesses of glass in your oven or kiln.

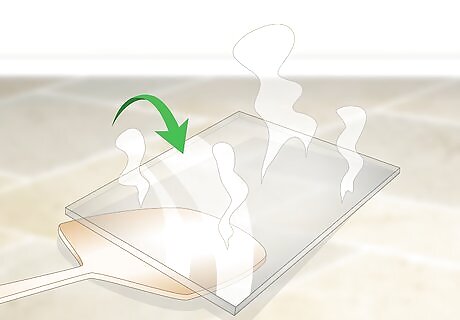

Remove the hot glass from the oven and set it on a brick or cement surface. Use tongs or a paddle made for handling hot glass. Remove it from the oven carefully and set it down on the surface to start the cooling process as quickly as possible. In facilities specially designed for tempering glass, there will be a special quenching oven that the glass gets transferred to after the oven.

Quench the glass with blasts of cool air for 3-10 seconds to cool it. Immediately start blasting the glass with cool air from high-pressure nozzles at various angles after you remove it from the oven. This causes the outer surfaces of the glass to contract and compress against the center by cooling them faster, which is what makes the tempered glass strong.Tip: Tempered glass has to have a surface compression of 10,000 PSI or higher. It will typically break under about 24,000 PSI. If you are tempering glass in a special facility with a quenching oven, the oven will have nozzles to blast cool air preset at different angles. If you are working with more limited resources, you can use a compressed air hose and move it constantly while blasting the glass to hit all the different angles. Tempered glass is about 6 times stronger than regular glass. When it does break, it will break into small shards that are much safer than the jagged pieces that regular glass (called floating glass) breaks into.

Check the glass with polarized glasses and by shining a light through it. Properly tempered glass has shadow-like patterns that you will be able to see through polarized lenses. These patterns are called “quench marks”. Shine a light through the glass to make them easier to see. These quench marks can look like dark, shady spots or lines that stretch across the surface of the glass.

Comments

0 comment