views

Measuring the Dimensions of the Old Window

Measure the width of the existing window in 3 places. To measure the width of the existing window, run your measuring tape from the jamb on the left side of the window to the jamb on its right side. Take a measurement at the top, middle, and bottom, and use the shortest distance as your true measurement. Open the window and look at the sides. Find the thin strips that run vertically on each side and sit flush against the moving part of the window, which is called the lower sash. These strips are called stops. The stops sit in front of the stash on the interior side of the window. The jambs, or the window's side posts, are past the stops and are in line with the sashes. Notice that the distance between the stops is shorter than the distance between the jambs. If you'd measured from the stops, your replacement window would be too small.

Measure the height of existing window. Take your measurements from the window sill to the head jamb. Look at the top of the window, and notice that there's another stop that runs horizontally. It's a bit lower than the head jamb, or the very top of the frame. Measure from the sill to the head jamb on the left, center, and right sides, and use the smallest number as your true measurement. With the window open, look at the bottom of the frame. The sill is where the sash sits. Don't confuse it with the stool, or the molding on the inside of the window that gives it a finished look. The stool is higher than the sill and, like the stops, would throw off your measurements. Sills are often sloped to divert water away from a home's interior. If your window sill is sloped, take the measurement from its highest point. Additionally, use a protractor to measure the angle of the sill's slope. Some replacement windows offer a choice of sill angles.

Check the squareness by measuring diagonally across the window. Run your measuring tape from the top left of the frame to the bottom right, and note your measurement. Then measure the frame diagonally from the top right to the bottom left. If there's a difference of less than ⁄4 to ⁄2 in (0.64 to 1.27 cm) between the diagonal measurements of your frame, you can make small adjustments with shims when you install the new windows. If the difference is any larger, consider contacting a professional.

Purchase a new window that fits your measurements. Carefully measuring the existing window is the most important step to replacing it. Bring your measurements to a home improvement store, consult an employee about available window sizes, and buy one that meets your needs. In general, the window should be ⁄2 to ⁄4 in (1.3 to 1.9 cm) smaller than the existing opening. You may need to purchase a custom window to fit your measurements. For the easiest and most energy-efficient option, go with vinyl replacement windows with their own self-contained jambs and sashes.

Removing the Old Window

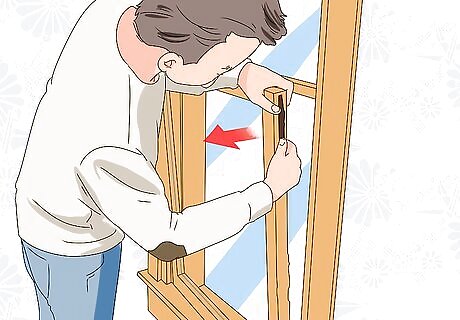

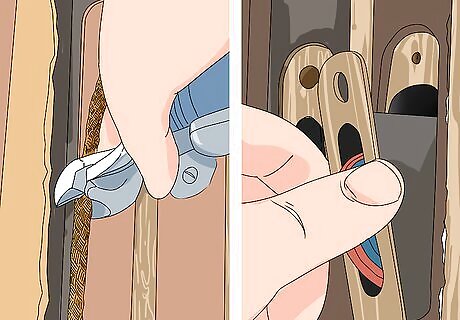

Remove the inside stop pieces from the sides of the window. Recall that the stops are vertical strips on either side of the window frame. Use a thin pry bar or stiff putty knife to carefully pull them off of the frame. If caked paint makes the job difficult, use a utility blade to score along the edge of the window frame. Do your best to avoid damaging the stops, as you'll reattach them once you've installed the new window. If you happen to crack a stop, take a bit of wood filler and mold it onto the damaged part. Let it dry for about 15 minutes, and sand down the filler and the surrounding wood. Then give it a new coat of paint before reattaching to the frame. If you accidentally snap a stop in half, either patch it together with wood filler or purchase a 1 ⁄2 by ⁄4 in (3.81 by 0.64 cm) furring strip from the hardware store. This should be the matching size, but measure your stop to be sure. Saw the furring strip to match the height of the other stop. EXPERT TIP Bicycle Glass Bicycle Glass Glassblowing Experts Bicycle Glass Co. was founded in 2016 by David Royce and Michael Boyd, two professional glass experts. Bicycle Glass is primarily a lighting company, committed to quality, sustainability, and affordability. All Bicycle Glass products are made of high-quality, recycled glass and are hand-blown by a dedicated team of artisans. The studio is committed to reducing its carbon footprint by conserving energy in all of its production. Using renewable wind energy to offset all electricity usage, the studio is actively working toward the goal of carbon neutrality. Bicycle Glass believes that high-quality, handmade glass products should be within reach for everyone. Bicycle Glass Bicycle Glass Glassblowing Experts Always prioritize safety when working with glass. Make sure to wear proper protective gear and carefully handle the glass. This applies to all processes, including holding, cutting, or polishing. Follow safety protocols to prevent accidents and achieve successful outcomes.

Take the inside sash out of the window frame. Once the inside stops are gone, the lower sash should slip out easily. If your existing window is old, the inside sash might be connected to a weight by a chain or cord. If necessary, cut the chain or cord and let the weight fall down into its well. If the lower sash doesn't slip out and you don't see cords, it might have metal jamb liners or springs. Look for nails or screws that secure spring boxes to the sash, and remove any you find.

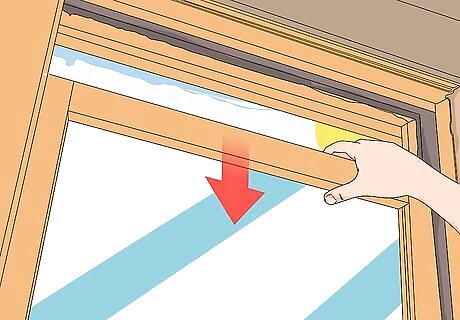

Slide the upper sash down to the bottom portion of the frame. Look for the thin strip of wood at the top of the frame that sits against the upper sash. This is the parting stop; remove it to free the upper sash. Then, pull out the upper sash; if it's a double-hung window, cut any chains or cords that connect it to a weight. In a double-hung window, both the upper and lower sashes open and close. Leave the exterior stops on the window frame. These outside strips are the counterparts to the inside stops, or the strips that you pried off the frame on the interior side of the window. The exterior stops will help guide the replacement window during installation.

Clean up the remaining window frame. Remove any weights and pulleys from their wells on the sides of the window frame. Look for old nails or screws, and remove any you find. Then scrape away old paint and caulk, and patch any holes with an exterior-grade wood filler. Wait at least 15 minutes for the filler to dry, sand it with 120-grit sandpaper, then paint it to disguise your work. Filler drying times may vary by brand and the depth of your repair, so check your product's specific instructions. If your window has weight wells, or cavities on the right and left sides, fill them with fiberglass or foam insulation after removing the weights. To cut down on clean up time, use a shop vac to remove peeled paint and other debris.

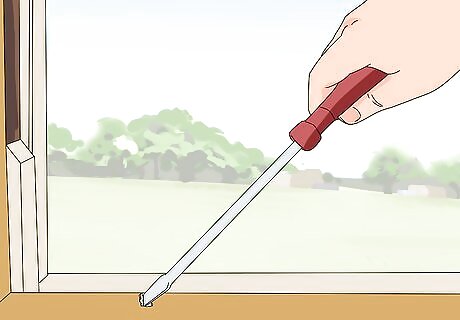

Check for rotted wood in the window frame. Run a flat-head screwdriver around the frame to probe for rot. If you notice soft spots or crumbing wood, call a professional to replace the window frame. Instead of trying to install the new window or reinstalling the old one, your best bet is to screw a plywood board over the exterior side of the window until your contractor can inspect it. A replacement window needs to be installed in a solid, rot-free frame, and a rotted frame could be a sign of larger structural problems.

Installing the New Window

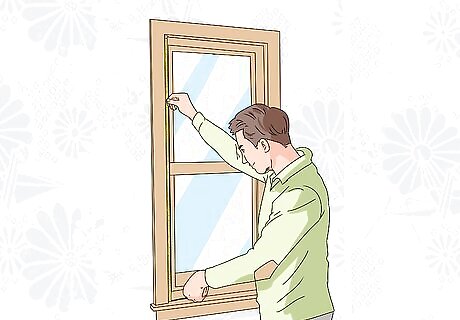

Place the new window into the frame to test its fit. Carefully lift the replacement window into place to dry fit it. There should be a ⁄2 to ⁄4 in (1.3 to 1.9 cm) gap around its perimeter. Once you've verified that the window is the right size, take it out of the frame and set it aside. A large window is heavy, so get help lifting it to avoid dropping it or injuring yourself. If you measured carefully, the new window should match the opening. If it's too small, you can add furring strips to the jambs to match the new window. For instance, if there'a a 1 ⁄2 in (3.8 cm) gap on either side of the new window, screw 1 in (2.5 cm) furring strips to the side jambs, or the posts on the left and right sides of the frame. If the new window is too large for the frame, return the window, if possible. If you can't exchange the unit, you'll need to cut into the raw opening. This is best left to a professional.

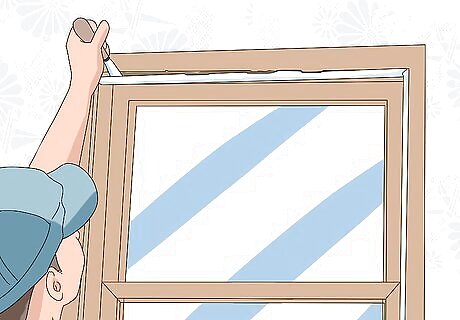

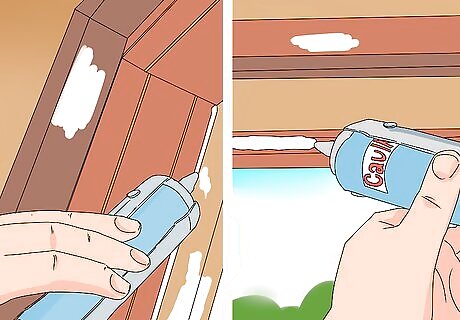

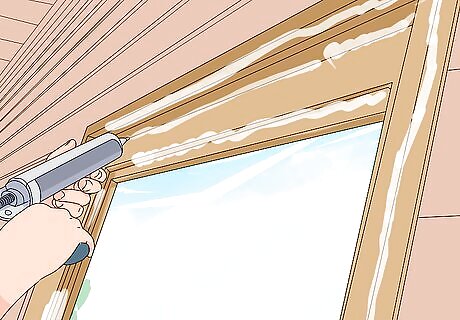

Run a bead of caulk along the exterior stops. Recall that you didn't remove the exterior stops, or the strips that sit flush against the outside of the sashes. Using a caulk gun, apply a ⁄8 in (0.95 cm) bead of waterproof, exterior-grade caulk along the top of the frame and sides of the stops. Then run 2 beads of caulk on the sill against the stool. The stool is the interior molding that sits on top of the sill to give the frame a finished look.

Set the new window into the opening. Slip the bottom of the window onto the sill, then tip its top into place. Press the window against the exterior stops, and ensure it's centered in the opening. Secure the window by loosely driving a 2 in (5.1 cm) screw through an upper side jamb. At this point, you just want to hold the window in place so you can check its function and, if necessary shim it. Most modern replacement windows have pre-drilled holes; drive the screw into one of the upper side jamb holes.

Open the sash and check for levelness. Open and close the sash, or the moving part of the window, to test its function. Lock and unlock the window, and ensure its parts work smoothly. If it doesn't open and close smoothly, check it with a bubble level. Add shims, or scraps of wood approximately ⁄8 to ⁄4 in (0.32 to 0.64 cm) thin, between the replacement window and the sill to prop up 1 side. Once it's level, trim the lengths of the shims that stick out with a utility blade or handsaw.

Drive mounting screws into each jamb. Use the screws that came with your kit, or 2 ⁄2 in (6.4 cm) galvanized mounting screws. Locate the replacement window's pre-drilled holes, and insert a shim into the small gap between the window and frame next to each hole. Then drive a screw into each pre-drilled hole. The screws should be snug, but not over-tightened. Placing shims by each pre-drilled hole will help secure the window and keep the frame from bowing. Trim the parts of the shims that stick out with a utility blade or handsaw.

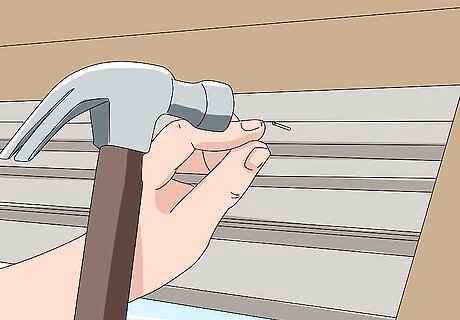

Replace the inside stops and any other trim you removed. Almost done! Hold 1 of the stops to the side of the frame where it was originally attached. Hammer 3 galvanized finish nails into the top, middle, and bottom of the stop to keep it in place. Repeat the steps to replace the inside stop on the other side of the frame. Depending on the design of your replacement window and condition of the existing frame, you may also need to use the same technique to hammer trim onto the exterior. Adding or replacing exterior trim can also give your windows a more polished look.

Caulk the exterior gaps between the window and casing. Head outside and caulk the exterior of the window. Fill gaps less than ⁄4 in (0.64 cm) wide with an exterior-grade caulk. Apply continuous beads between the replacement window and existing frame. Be sure not to caulk the gap between the sashes and the jambs of the replacement window. The jambs of the replacement window frame the sash, or the parts that open and close. The boundary between the existing frame and the outside of the replacement window is the gap you want to caulk. Otherwise, the window wouldn't be able to open! Use foam-rubber backer rod to fill gaps larger than ⁄4 in (0.64 cm). Insert the rod into the gap, then apply beads of caulk over the rod to seal it.

Comments

0 comment