views

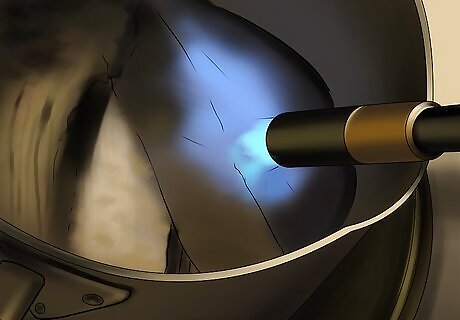

Remove the old bearing. Babbitt bearings are solid and must be melted off with an oxy-acetylene torch, available at hardware and building supply stores. Open the bearing case and melt off the old bearing, making sure you melt the retaining grooves and holes, as well. Collect the melted Babbitt in a cast iron lead melting pot, available at welding supply outlets. Scrape remaining Babbitt from the bearing case, grooves and holes and add them to the pot.

Get more Babbitt. You should not reuse the Babbitt that has been melted off due to impurities from years of use. Determine which alloy of Babbitt that you need. You can determine which alloy is needed with the surface speed of the shaft and the load the bearing is going to be caring. Tin and Lead based Babbitts have different compositions for different loads and uses. The formula in the following reference will help you to find which Babbitt alloy is right for your bearing. Babbitt metal is usually available at sawmill supply companies, chipper companies or some hardware stores. It is also available to be ordered directly from manufactures like Kapp Alloy.

Prepare the surfaces. Bearing surfaces are then typically cleaned with a solvent to remove any oil or other contaminant residues. On very well-worn and old surfaces, this can be the most difficult part of the bearing refurbishment. Often, the lubricants and contaminants have worked well into the steel and old bearing Babbitt. You may find that you think the surface is clean, but on heating, more contaminants and oil surface from the steel. These contaminants can be drawn out by alternating: a. heat while scrubbing with a stainless steel brush, and b. solvent treatments. Removing these contaminants is critical to a uniform Babbitt bond. Make sure that the shaft to be supported by the bearing is smooth and clean.

Coat the shaft. To prevent the shaft from sticking to the bearing, coat the shaft with smoke from a low flame kerosene lamp or a candle.

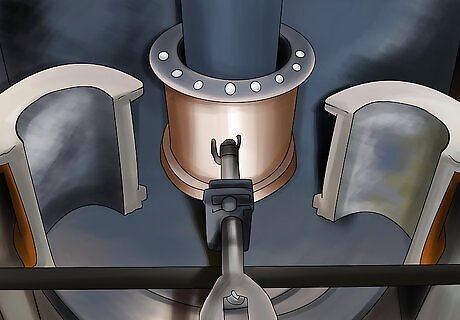

Position the parts. Place the bearing shell in the vertical position. Align the shaft in the exact middle of the bearing shell. Plug or dam the holes in the bearing, except for the fill hole. Clay, wood, sheet metal and fireproof pasteboard can all be used to plug the holes.

Melt the Babbitt metal. Use the cast iron lead melting pot. Heat the Babbitt metal to the desired pouring temperature depending on the Babbitt alloy. An electric lead pot designed to cast bullets is the preferred method because the pot has a temperature control. The melters typically are available at armory supply shops and specialty forging shops. These outlets also should be able to provide a bullet caster's thermometer, which is used to ensure that the Babbitt metal is at the desired temperature.

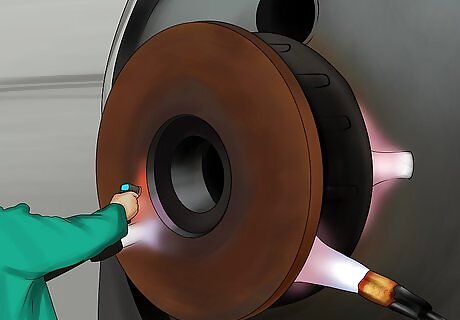

Heat the bearing shell and the shaft. This will minimize the thermal shock when pouring and yield a properly formed and consistent bearing. Heat the bearing shell and shaft to about 250 degrees F (121 degrees C) so that moisture will evaporate quickly, but not sputter.

Skim clean the molten Babbitt metal. When the Babbitt metal has reached the proper temperature, stir the fluid. Skim off any dross (impurities) that have floated to the top of the molten metal.

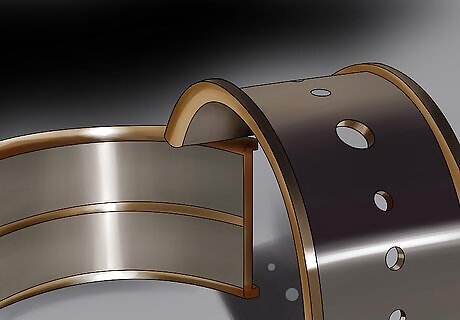

Pour the bearing. Pour the molten Babbitt metal into the bearing shell. If the ladle is not big enough to fill with 1 pour, work quickly to get the second pour in so that no boundary forms between the 2 pours.

Finish the bearing. Allow the bearing to fully cool. Use a drill to drill out the oil holes. Clean any excess material from the drilling. Use a diamond shaped chisel to chisel an oil groove from the oil holes to about 0.25 inches (6.35 mm) from the end of the bearing. The oiling groove must be cut on the inside surface of the bearing, so the bearing must be driven off of the shaft for the chiseling and then replaced. Clean any excess material left from the chiseling.

Comments

0 comment