views

Gathering Tools and Preparing for Disassembly

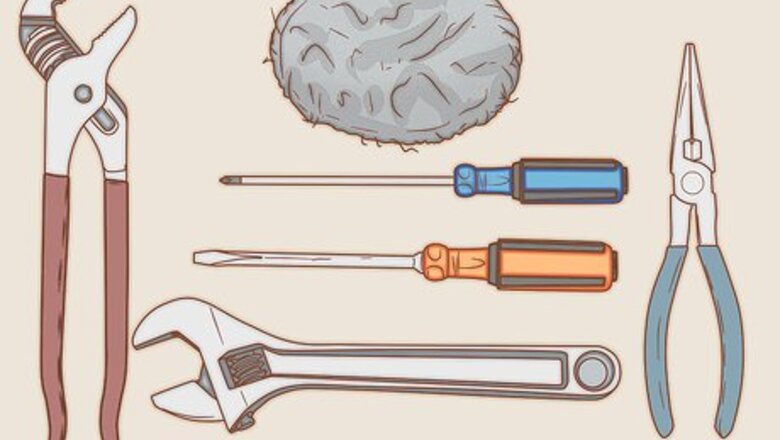

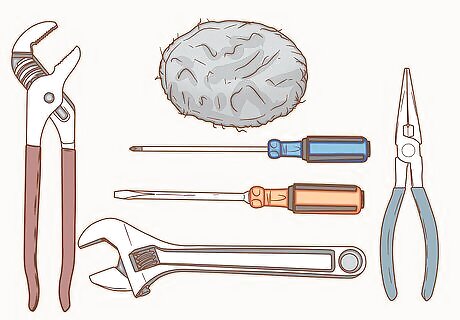

Grab the tools you’ll need for this job. Luckily, these are all basic tools that you’ll probably find in your toolbox. You’ll need the following: Crescent wrench Flat-head screwdriver Phillips screwdriver Adjustable pliers Needle-nose pliers Steel wool

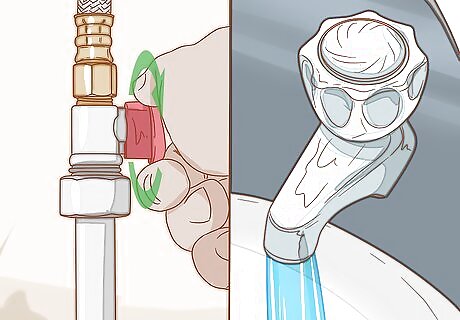

Turn off the hot and cold water supply and drain the lines. Peek underneath your sink and locate both shutoff valves—they’ll be at the lower end of the 2 flexible water supply lines that connect to the underside of the sink. Turn them clockwise until they are fully closed. Then, turn on the hot and cold faucet taps and drain the water from the lines. If the water supply won’t shut off completely, you’ll have to replace 1 or both shutoff valves. Unless you have some plumbing experience, it’s probably best to call a professional to do this repair.

Plug the drain to prevent losing any faucet pieces down the pipe. Simply jam a piece of cloth or a small wad of paper towel into the drain. You don’t want to lose one of the small pieces of the faucet assembly down there! If your sink has a stopper that fully blocks the drain opening, you can use that instead.

Removing the Tap Stem

Pry the cover off the faucet tap with a flat-head screwdriver. Compression faucets have screws in each tap (hot and cold) that are concealed beneath plastic or metal caps. These caps often have the H (hot) and C (cold) indicators marked on them. Wedge the blade of a flathead screwdriver beneath the cap and pop it off. You’ll usually find a small indentation somewhere beneath the rim of the cap—if you do, wedge your screwdriver into this spot. If you’re only replacing the washer on 1 tap (e.g., cold), don’t bother popping the cap or working on the other tap (e.g., hot). But this might be a good time to replace the washers on both taps.

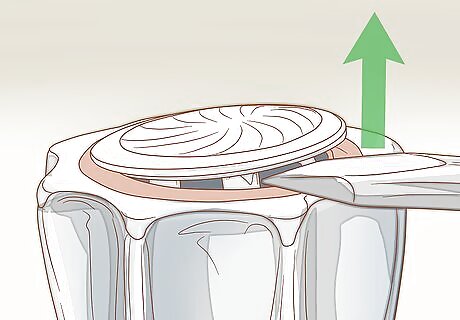

Remove the screw located under the cap, then remove the handle. Turn the screw counterclockwise until it comes free, then remove it. After this, you’ll be able to lift the tap handle and remove it from the tap stem. Depending on the type of screw, you may need to use either your flathead or Phillips screwdriver. Don’t lose track of this screw or any of the other parts you remove—you’ll need them later!

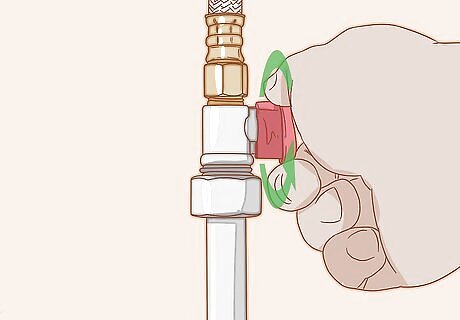

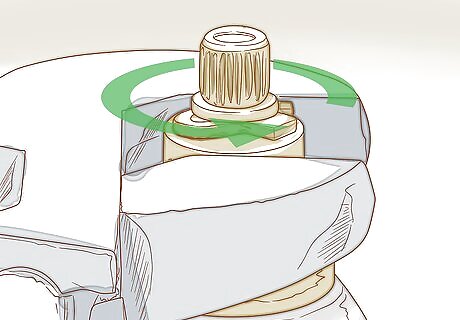

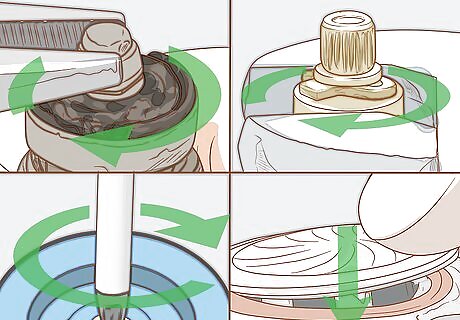

Loosen the hexagonal packing nut so you can pull out the tap stem. Adjust your crescent wrench so it fits snugly around the packing nut, then turn counterclockwise until it releases. At this point, you can lift the tap stem up and out of the sink. In some cases, you may have a compression-style sink with separate faucets—that is, a hot faucet and cold faucet, each attached to their respective handles. If so, grip the faucet with one hand while you loosen the packing nut with the wrench in your other hand. Then pull the tap stem up and out of the faucet. If the packing nut won’t budge, try spraying it with a lubricant like WD-40, then wait 5-10 minutes and try again. If it still won’t move, call a plumber so you don’t cause damage to your sink trying to get it out.

Replacing the Washer and Finishing the Job

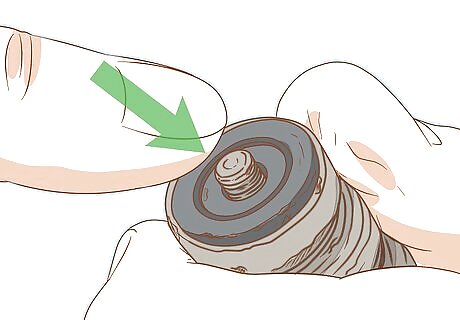

Remove the screw or nut and rubber washer from the bottom of the tap stem. Many tap stems have a small nut or screw that holds the rubber washer in place at the bottom. If you find this, use a screwdriver or adjustable pliers to remove the screw or nut. Then, pluck off the rubber washer with needle-nose pliers.

Take the old rubber washer to a hardware store to find a match. Tap washers vary in size and thickness based on the faucet make and model. Your best bet is to remove the old washer and use it to find a precise match. You’ll find rubber washers of practically every size at your local hardware store or home improvement center. Alternatively, you can cheaply buy a collection of various rubber tap washers beforehand, and use the closest match during your repairs. But it’s best to use a perfect match whenever possible.

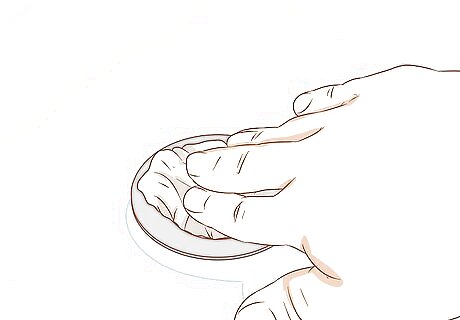

Place the new washer and old screw/nut onto the bottom of the tap stem. Use your fingers or the needle-nose pliers to slide and press the new washer into place. Then, if your tap stem uses a screw or nut, use the screwdriver or pliers to tighten the screw/nut back in place. Depending on the tap stem model, the washer might press into an indentation in the bottom or slide over the end of the stem and into a channel. Your best bet is to place the new washer in the same spot where you found the old one.

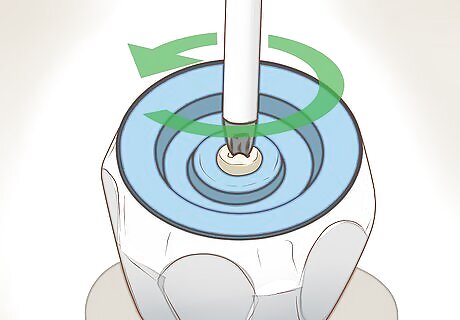

Clean off any limescale on the tap stem and tap seat with steel wool. If you see any white limescale or other debris on the surface of the tap stem, rub it away with a piece of steel wool before reinstalling it. Likewise, use your finger to stick the steel wool into the opening of the tap seat (where the tap stem inserts into the sink or faucet) and twist it a few times to release any limescale. If you loosen any limescale or debris inside the tap seat, try to wipe it out with a paper towel wrapped around your finger.

Reinstall the tap stem, packing nut, handle, screw, and cap. Reassembling the tap is the same as disassembling it, only in reverse. You’ll need to: Insert the tap stem into the tap seat; Tighten the packing nut with a crescent wrench until it’s snug; Place the handle over the tap stem; Tighten the screw that holds the handle in place with your screwdriver; Press the cap over the screw until it snaps into place.

Turn on the water supply and test for leaks. Twist the hot and cold shutoff valves counterclockwise to turn the water supply back on, then open both faucet taps. Allow the water to run at full force for at least 2-3 minutes. Check for leaks around the base of each faucet tap during this time. After that, turn off the water and see if the faucet drips. If nothing leaks, you're all done! If there is a leak, then the washer likely wasn’t the culprit in the first place. In many cases, the problem is a rutted or damaged tap seat. It’s possible to repair/replace the tap seat yourself if you have some plumbing skills, but it’s better to call a plumber if you’re a novice.

Comments

0 comment