views

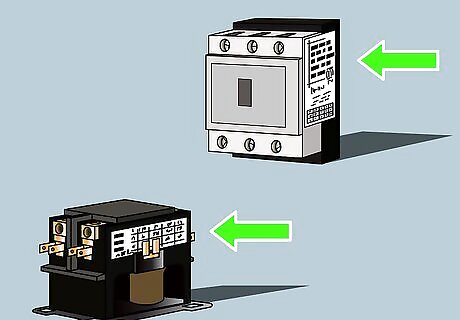

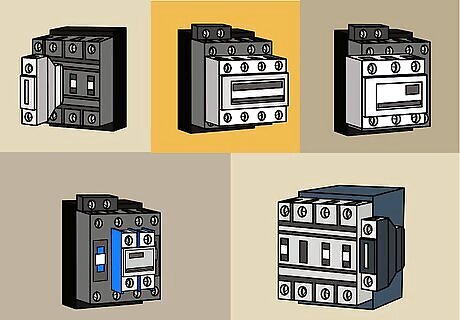

Acquire the contactor. Make sure that the contacts of the contactor are rated in both voltage and current to handle the expected load that will be required by the equipment being powered. Contactors are available from building and construction supply stores, as well as some larger hardware stores.

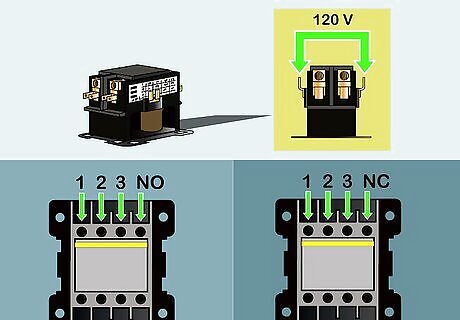

Study the contactor manufacturer information. The manufacturer information will identify the 2 input pins for 120 volts AC control. The may be 2 or more sets of output contacts identified. These contacts may be indicated on the label as normally open (NO) and normally closed (NC). These contacts also may be shown as a drawing of a line from 1 contact ending in a dot (the NC contact) and another line from another contact that is near the dot, but does not touch the dot (the NO contact.)

Check for an auxiliary output contact. Some contactors provide an auxiliary output contact as a signal to the isolated part of the circuit that the contactor has been energized. This auxiliary contact will not be rated at the higher voltage. Instead, it should be rated at 120 volts AC.

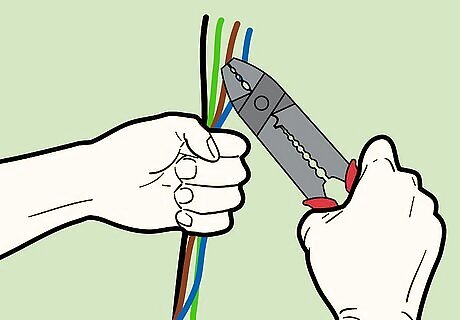

Route the wires. Remove all power to the wires. Run all input and output wires to the contactor. These wires should be rated in the manufacturer information. Use wire strippers to cut excess length off of the ends of the wire, making sure that the wires are long enough to reach the intended contact. Wire strippers are available at hardware stores and electric supply stores.

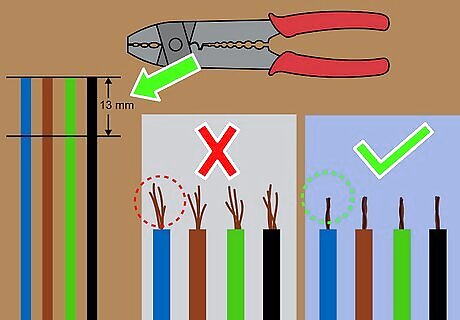

Strip the wires. Use the wire strippers to strip a half inch (13 mm) from the ends of each wire. If the wire is stranded, twist the exposed wire to ensure that no strands are left hanging. Stray strands may make unintended contact with a piece of the equipment and cause damage.

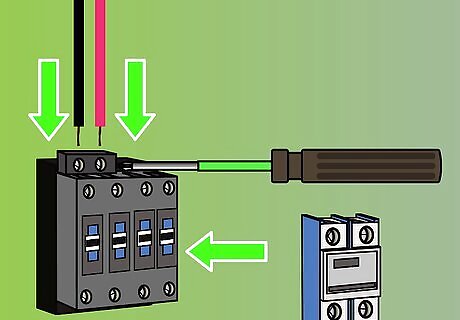

Wire the inputs and the auxiliary contacts. Use a screwdriver to loosen the holding screws in the contact blocks for the wires. Insert the wires only so far that no insulation is pushed into the contact area of the block. Make sure that no stray strands are jutting out from the contact block. Tighten the screws on the contact blocks.

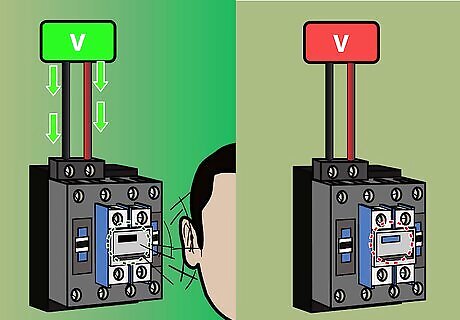

Energize the contactor. Apply the control voltage to the input. Listen for the contactor to click as it engages. De-energize the contactor.

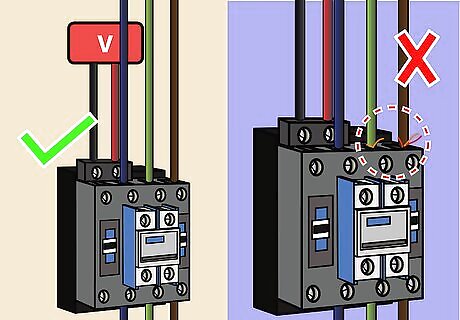

Connect the outputs. Put the stripped end of each wire into the appropriate contact block after loosening the screw of the block. Make sure that no stray strands of wire are jutting from the contact blocks. Tighten down the screws of the contact blocks.

Comments

0 comment