views

Pulling out an Exposed Pin with Pliers

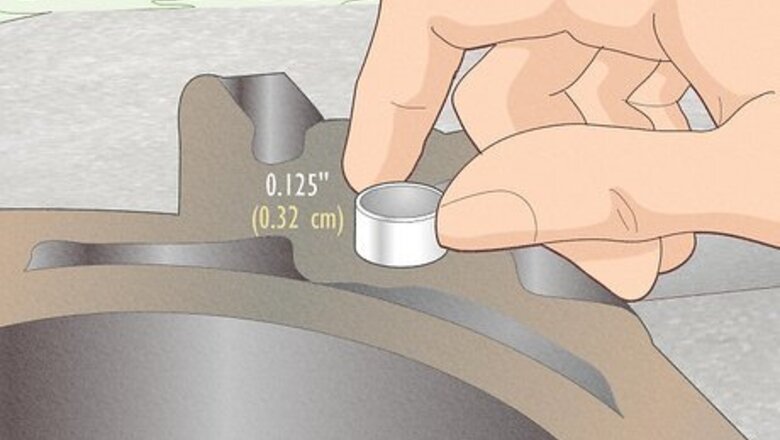

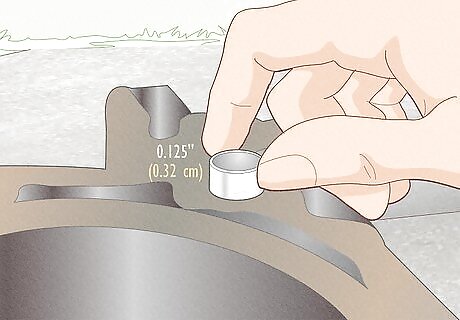

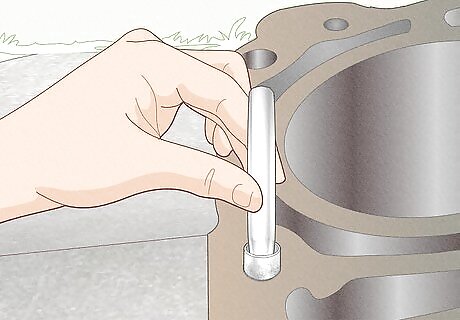

Check that the pin is intact and is at least 0.125 in (0.32 cm) exposed. Examine the tight dowel pin to make sure it is not broken, collapsed, or otherwise damaged. Measure the exposed section of the pin to make sure it is at least 0.125 in (0.32 cm) above the surrounding surface. This method can be applied to dowel pins in any type of engine casing. If the pin is damaged or there is not enough of it exposed above the surface, you probably won’t be able to pull it out. If this is the case, try filling it in with a punch or drill bit and pulling it out with pliers instead.

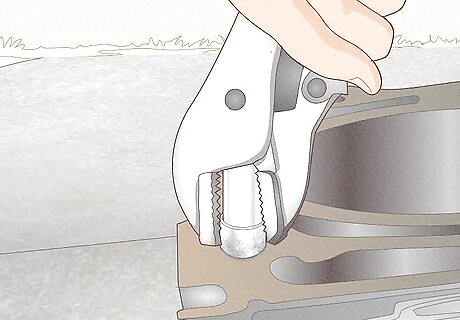

Clamp a pair of pliers around the exposed end of the pin. Grip the exposed part of the dowel pin between the jaws of needle-nose or regular pliers. Hold the pliers firmly enough that the pin doesn’t slip out when you pull. Be careful not to squeeze the pliers too hard or you might end up collapsing the dowel pin and making it harder to get out. If you’re trying to pull a dowel pin out of a smaller part that moves around, clamp the part in a vise first to stabilize it.

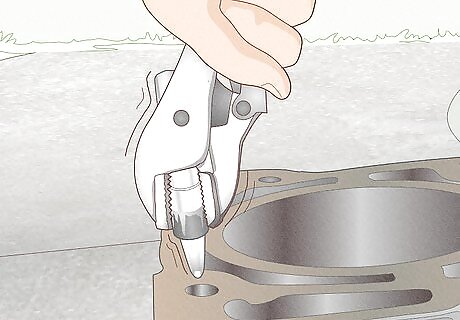

Pull the dowel pin straight out without angling or wiggling it. Keep squeezing the exposed end of the pin in the pliers. Pull straight away from the hole to try and remove the tight dowel pin. Avoid angling or wiggling the pliers while you attempt to pull the pin out. You might damage it and make it get even more stuck. If you aren’t able to pull the tight dowel pin out this way, move on to the next method. If it’s stuck, it’s stuck, so don’t try to muscle your way through it.

Using a Punch or Drill Bit

Get a tapered punch or a drill bit that’s smaller than the pin’s diameter. Use a tapered punch that will fit into the pin without passing all the way through for the best results. Use a drill bit that is only slightly smaller in diameter than the pin, so that it will fit tightly inside the pin, as an alternative if you don’t have a punch available. If the dowel pin is collapsed at all, a drill bit won’t work. Use a punch so that when you tap it in it will spread the dowel pin back open. This method usually works to remove stuck dowel pins that you’re unable to pull out using just a pair of pliers, either because they’re just too stuck, not exposed enough to get a good grip on, or collapsed or damaged in some way.

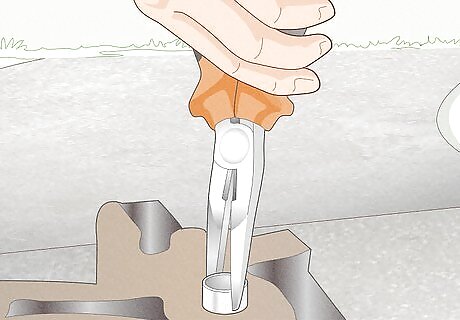

Place the tip of the punch or the backside of the drill bit inside the pin. Stick the tip of the punch into the dowel pin as far as you can by hand if you’re using a tapered punch. Push the backside, or the smooth side, of the drill bit as far as you can get it into the pin if you’re using a drill bit. Filling in the center of the dowel pin allows you to squeeze it way more tightly as well as wiggle and twist it to pull it out with a pair of pliers.

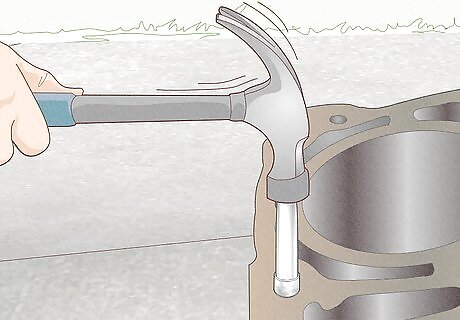

Tap the punch or drill bit into the pin using a hammer until it’s snug. Give the backside of the punch or the tip of the drill bit a few good whacks with a hammer until the punch or drill bit is sitting securely inside the dowel pin. The dowel will stick snugly to the object to make it easier to pull out. If the drill bit feels snug after pushing it in by hand, you can give the next step a shot instead of using a hammer to tap it in. It’s more important to tap a punch in since it’s tapered.

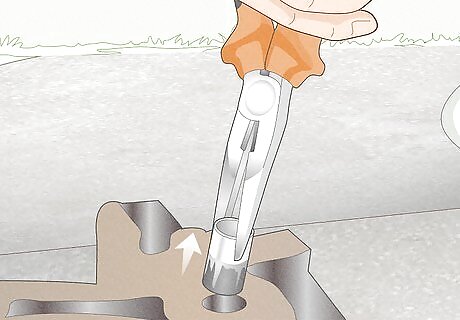

Grip the dowel pin and punch or drill bit as tightly as possible with pliers. Use a pair of vise-grip pliers for the best grip or any other pair of pliers you have handy. Squeeze the part of the dowel pin where it sits on top of the punch or drill bit as hard as you can. Since the middle of the dowel pin is filled in by the punch or drill bit, you don’t have to worry about collapsing it. Leave a small gap between the pliers and the engine casing so you don’t scratch it while you wrestle with the dowel pin.

Twist and wiggle the pin while simultaneously pulling until it comes out. Keep squeezing the pliers tightly and twist them back and forth to loosen the pin. Pull the dowel pin straight out when it starts to loosen. You’ll probably notice that the dowel pin you got out is corroded, which is why it was stuck in the first place. You should discard and replace it with a new one to avoid the same problem in the future.

Comments

0 comment