views

Preparing the Insect for Preservation

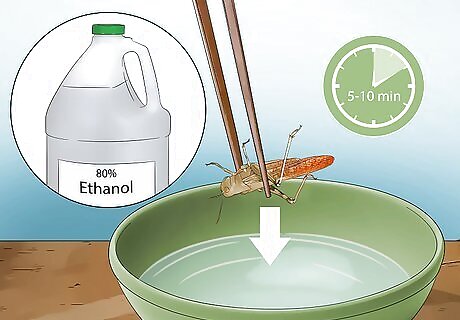

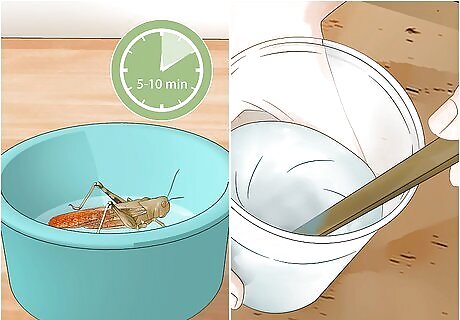

Sanitize the insect in alcohol for at least 5-10 minutes. Ethanol (70%-80%) is the best choice here, but isopropyl (rubbing) alcohol (70%-80%) is easier to find and gets the job done. Add the insect to a cup, bowl, or jar of alcohol for at least 5-10 minutes to kill bacteria, or seal it in a glass jar of alcohol for days, weeks, or even months until you’re ready to preserve it in resin. If you’re catching a live insect to preserve, putting it in alcohol for at least 10 minutes will kill it while also cleaning it. But also keep in mind that it’s usually fairly easy to find dead insects that are still intact if you’re willing to look around for them. You may get better preservation results with living soft-bodied insects (like caterpillars, grubs, and larvae) by putting them in boiling water for 1-2 minutes. After that, transfer them to a container of ethyl or isopropyl alcohol.

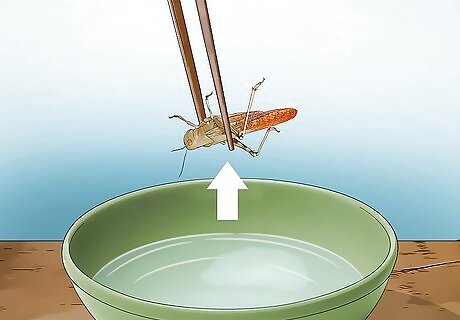

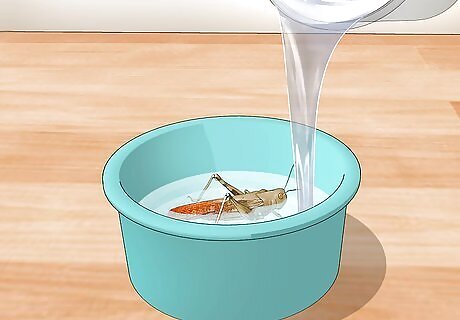

Remove the insect from the alcohol and let it air dry. It’ll take around 5-30 minutes for the insect to dry completely, depending on its size and how long it’s been soaking. Since you’re aiming to do a simplified preservation process, move straight on to preparing the resin for casting. If you’re interested in doing a more detailed preservation process that’s closer to what professional entomologists do, skip this step and check out the “Advice for More Detailed Preservation” section of this article before proceeding. While it’s definitely more time-consuming, the detailed process reduces the chance of the insect rotting inside the resin and increases the visual appeal of the insect’s appendages.

Set up in a ventilated area with safety gear before mixing the resin. It’s extremely important to work with resin in a highly-ventilated location, such as in a garage with all the doors and windows open. For additional safety, wear disposable gloves, protective eyewear, and a protective mask that filters out the resin fumes. Check the specific safety recommendations for the brand of resin you’re working with. Insect preservationists typically use one of several brands of clear polyester casting resin.

Setting the Insect in Resin

Stir together a small batch of resin in a disposable container. A clear disposable plastic drink cup is a good choice here. Resin is made by combining the resin base with the catalyst. You should follow the specific mixing instructions on the resin package, but here’s a typical mix to make a base layer for 4-5 individual molds: pour ⁄2 in (1.3 cm) of resin base in the bottom of the cup, add 40-45 drops of the catalyst, and stir slowly but thoroughly with disposable wooden tool (like a crafting stick or chopstick) for about 1 minute. Stir slowly so you don’t add lots of air bubbles into the resin. These will show up in the finished product. It’s impossible to completely clean out the mixing container once you mix resin in it, so always opt for something you can throw out. However, do not use a styrofoam cup or bowl, since it may react with the resin.

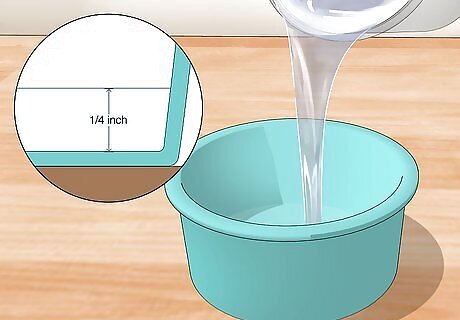

Slowly pour a ⁄4 in (0.64 cm) resin layer into a silicone mold. Silicone baking molds are great for at-home insect preservation, since the hardened resin pops out easily. (But, to be safe, don’t use them for baking any time afterward!) Pour a slow drizzle of the mixed resin into the silicone mold until it the base layer is about ⁄4 in (0.64 cm) deep. Pour slowly to cut back on the number of air bubbles you introduce into the resin. Ice cube trays work okay for smaller bugs, especially if they’re made of silicone instead of hard plastic. Silicone molds made specifically for resin casting are available online and in some craft stores. Try these if you need shape and size options that you can’t get with baking molds.

Wait about 30 minutes for the resin to get thicker (but not gelatinous). This thickening process can take anywhere from 20-50 minutes, but typically takes about 30 minutes. Starting at about 15 minutes, poke at the surface of the resin with a clean toothpick every few minutes. It’s ready for the next step once the consistency is somewhere between heavy cream and sour cream—do not wait so long that a gelatinous “skin” forms on top. While poking with the toothpick to check the thickness of the resin, take the opportunity to pop any air bubbles that are near the surface.

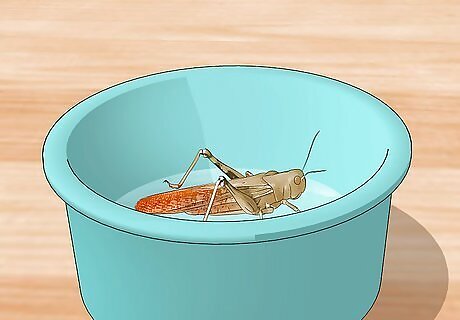

Very gently press the insect into the resin with tweezers. Use the tweezers to carefully center the insect on the surface of the base layer of resin, right-side up. Press down on its back ever so slightly so that the underside of the insect becomes set into the resin. Don’t press down so hard that the insect touches the bottom of the silicone mold. If the insect floats freely, the resin hasn’t set up enough. Carefully remove the insect and wait a few more minutes before trying again.

Mix more resin while the base layer gelatinizes in 5-10 minutes. Once you lightly press the insect into the thickened resin, it’ll take roughly another 5-10 minutes for a gelatinous “skin” to form on the resin—test it with a clean toothpick to be sure. While waiting, make more resin by following the same mixing ratio as before. However, mix up more resin this time if necessary—you want enough resin to cover the top of the insect by at least ⁄4 in (0.64 cm).

Finishing the Preservation Process

Submerge the insect in another layer of resin, again pouring slowly. The slower you pour, the fewer air bubbles you’ll add to the resin. Keep pouring until there’s at least a ⁄4 in (0.64 cm) layer of resin covering the top of the insect. As the resin begins to thicken over the following 20 minutes or so, you can use a toothpick to pop any air bubbles that appear. Don’t try to pop bubbles once the resin becomes gelatinous.

Allow the resin to set in the mold for at least 24 hours. The resin should be fully hardened within 24 hours, but the surface will remain tacky for a few more days. Give the resin 3-4 days before unmolding it, if possible. No matter how careful you’ve been, there will almost certainly be some air bubbles trapped in the resin. Just accept them as part of what makes your preserved insect unique!

Pop the resin-preserved insect out of the silicone mold. Don’t worry—the hardened resin will release from the silicone mold without any difficulty. Press up from the underside of the mold while peeling it away from the sides of the resin. At this point, your creation is ready for use as a paperweight, a jewelry pendant, or just a really interesting conversation piece.

Advice for More Detailed Preservation

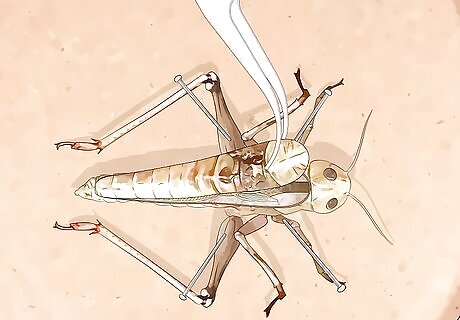

Empty the abdominal cavity and sterilize it with alcohol. Take this step after soaking the intact insect in alcohol for at least 10 minutes. To remove the innards of a medium or large insect, use a very sharp crafting knife to slice open the underside of the abdomen, then carefully clear out the cavity with tweezers, cotton swabs, toothpicks, and similar fine tools. Clean the tools in alcohol to sterilize them, then use them to fill the cavity with small pieces of alcohol-dipped cotton balls so it retains its shape. If the insect is too small to cut open, or you’re just not interested in cutting it open, use a needle to inject the abdominal cavity with alcohol. If you don’t take this step, the innards may potentially rot while the insect is encased in resin, which does not totally prevent air penetration. If this happens, the abdomen may shrivel up, discolor, and possibly ooze out some unpleasant-looking gunk!

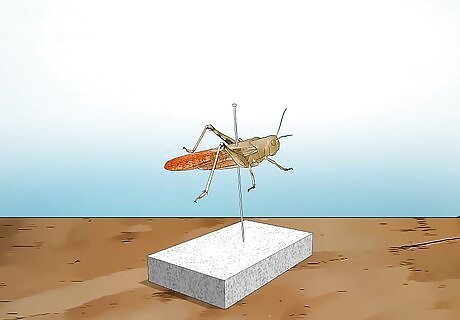

Pin the insect into its display position on a styrofoam block. Do this after removing or sterilizing the innards. Lay the insect right-side-up on a scrap of styrofoam, then carefully run a #2 or #3 insect pin through it to hold it in place—the ideal spot varies somewhat by insect, but is typically slightly off-center and about one-third of the way down the thorax. Use tweezers to spread out the legs, antennae, wings, etc., as desired, then press pins into the styrofoam (not through the appendages) to hold them in place. Make sure you arrange the insect exactly as you want it to dry within 1 day of its death. If you wait too long and try to move the parts of the insect, they are likely to break off. For insects with delicate wings, pin down thin strips of wax paper over the wings to hold them in position. Don’t put pins through the wings. Insect pins are available online and at some craft stores. Avoid using regular household pins if you can, since they might rust and discolor your insect specimen. If you leave the insect out to dry without pinning it, its appendages may twist, curl, and shrivel in undesirable ways.

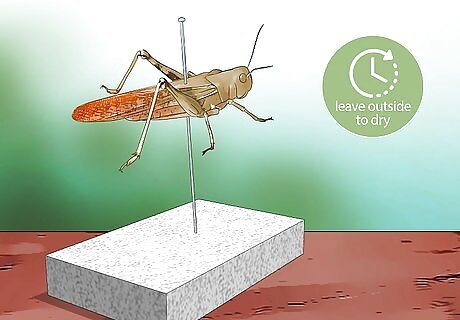

Leave the pinned insect out to dry until its body is rigid. The body of an insect with a hard exoskeleton may become rigid in 2-3 days, while a soft-bodied insect may take 7-8 days. To play it safe, set the pinned insect in a dry, airy spot for a week. Remove the pin(s) holding an appendage in place and see if it holds its position. If so, the insect is sufficiently rigid. Once the insect is rigid, carefully remove the pins so it’s ready to be encased in resin.

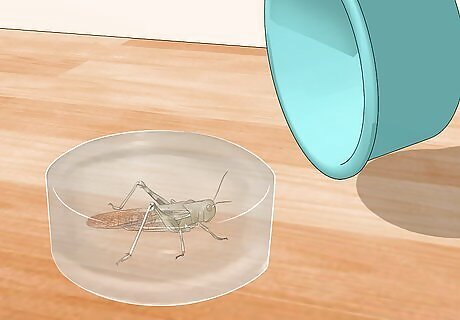

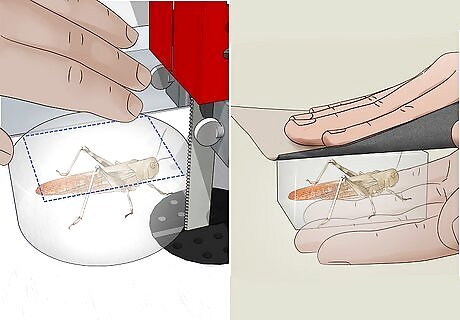

Cut the resin with a band saw instead of popping it out of silicone. Entomologists who cast insects for scientific purposes want resin blocks with perfectly straight and smooth edges, which isn’t possible if you use flexible silicone molds. This level of precision requires the following: casting the resin and insect in a petri dish; cutting the result out of the dish and into a straight-sided block with a band saw; and smoothing the block with a belt sander and buffer.

Comments

0 comment