views

Rendering the Fat

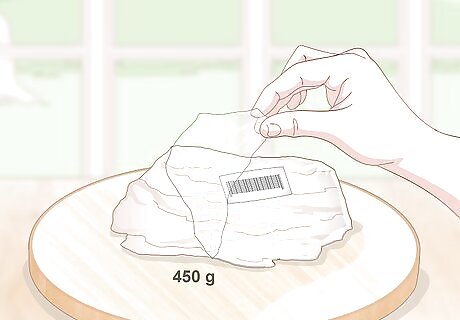

Purchase or gather around 1 lb (450 g) of animal fat. Any form of animal fat will work excellently for making glycerin, but pork or beef fat is usually the most common or easy to come by. Trim the fat away from meat before cooking it, or ask at your local butcher if they have any animal fat that you could have or purchase. You can save animal fat for later use by freezing it in an airtight container. Use a sharp knife to cut away the fat from a pork or beef roast before cooking it. Many butchers will throw away excess fat, so they’ll usually be happy to get rid of it.

Cut the fat into 1 in (2.5 cm) cubes. Cutting the fat into smaller pieces will make it quicker and easier to render. Use a sharp knife to cut your animal fat into rough cubes, no bigger than 1 in (2.5 cm). To reduce the amount of time the fat takes to render, you could cut it into smaller pieces or even grind it in a meat grinder or food processor. The smaller chunks of fat will render more quickly. Freeze your fat beforehand to make cutting it much easier.

Add the fat and water to a large stock pot. Transfer the fat to a large stock pot so that it creates a thin layer across the bottom. Measure out around ⁄4 cup (59 ml) of cold water and pour it over the fat. The water should just cover the bottom of the pot. Adding the water to the pot will prevent the fat from burning when it first starts to cook, letting it render better. Avoid adding too much water, as it won’t be able to evaporate in time for the fat to render properly. Around ⁄4 to ⁄2 cup (59 to 118 ml) should be plenty.

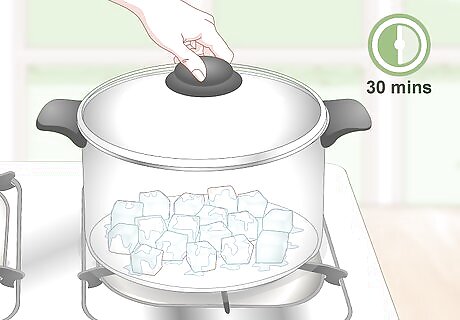

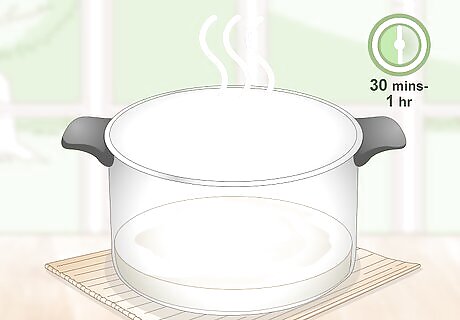

Cover the pot and cook over low heat for 30 minutes. Transfer the pot to your stovetop and begin cooking it over low heat. Add a lid to prevent the water from evaporating too quickly, and leave the fat to render for around 30 minutes. You could also render the fat in a slow cooker, leaving it to render on low for 3 to 4 hours. Cover the slow cooker or crockpot with a tea towel to prevent flies from getting into it. Alternately, you could render the fat in the oven. Add the fat and water to a dutch oven and cook it in a 225 °F (107 °C) oven for around 2 hours, stirring occasionally.

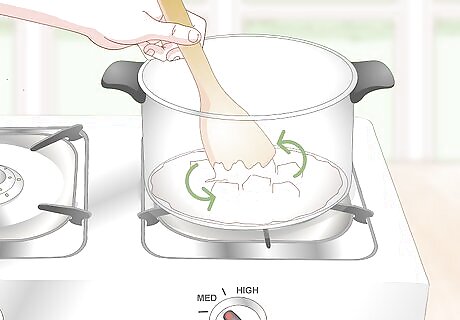

Increase the heat to medium and stir the fat every few minutes. After 30 minutes or so, the softer fat should have rendered and will prevent the unrendered fat from burning. Remove the lid and increase the heat to medium. Use a wooden or metal spoon to slowly stir the fat around every 5 minutes or so, until the fat is melted and completely rendered. Fully rendering the fat will take around another 30 minutes to an hour. Any remaining skin attached to the fat should crisp up once all of the fat has rendered from it. If you are using pork fat, keep the crispy skin aside and salt it for a tasty snack.

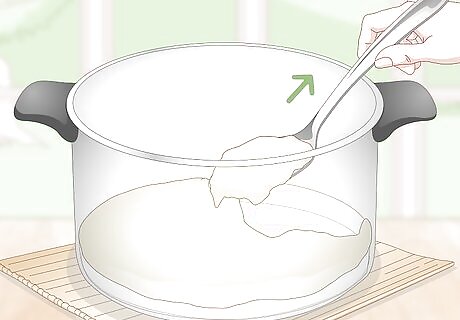

Strain the rendered fat through a fine sieve and cheesecloth. Remove the rendered fat from the heat and leave it to cool slightly. Line a fine-mesh sieve with 1 to 2 layers of cheesecloth and position it over a bowl or jar. Pour the fat into the sieve to strain away any meat, gristle or bone shards, leaving you with pure and rendered fat. Your fat should still be liquid when you strain it. Allow it to cool slightly for a few minutes, but not so much that it begins to solidify. Rendered fat can be kept in an airtight container in your refrigerator for around 1 month. If you store it in the freezer, the fat should last for up to 1 year.

Cooking the Soap Mixture

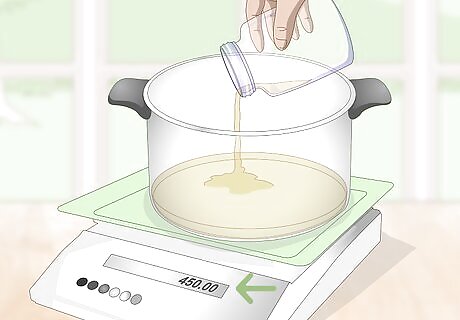

Weigh out 1 lb (450 g) of rendered fat into a large pot. Place a large pot onto a set of kitchen scales and set the display back to zero. Slowly scoop in or pour in your rendered animal fat until you have as close to 1 lb (450 g) as possible. Getting the measurements exactly right is crucial, as soap-making and glycerin making rely on a precise chemical reaction. Not having the right amount of fat can lead to caustic soap or glycerin that can be very harmful. If you want to alter the exact measurements for your own soap recipe and the type of fat you are using, look online for a soap making calculator. There are plenty that will allow you to enter the amount and types of fat you are using and give you precise instructions for the right ratios.

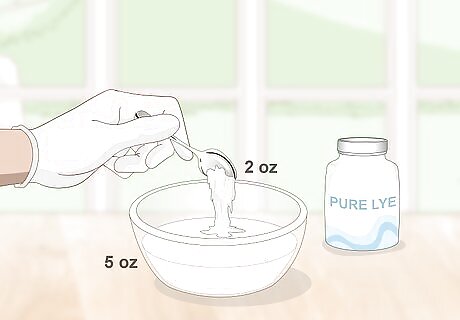

Stir 2 ounces (57 g) of lye into 5 fluid ounces (150 ml) of water. In a separate jug or bowl, measure out 5 fluid ounces (150 ml) of room temperature water. Slowly add in 2 ounces (57 g) of lye, stirring constantly as you do so to incorporate it fully. Leave the lye and water mixture to react and cool down. The water and the lye will combine and create an exothermic reaction, meaning the mixture will heat up. You should always wear protective gloves and eyewear when working with lye, as it is a caustic substance that eats away at fat. If you get any lye on your skin, remove any clothing the lye may have touched and flush the skin with cold water for 15 minutes. Seek medical attention immediately. Lye may be available in the cleaning section of your local grocery store. It should be easily available online or at a specialty soap-making store.

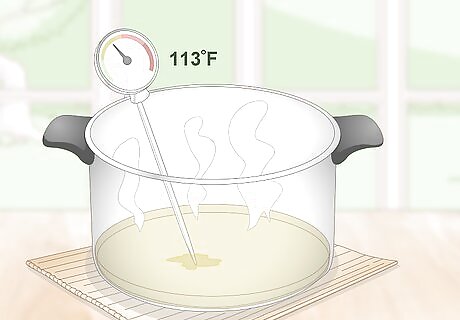

Bring the fat to 113 °F (45 °C) and place it on a heat proof surface. Use a candy or other food thermometer to check the temperature of your rendered animal fat. Place the pot over low heat to slowly bring the temperature up to 113 °F (45 °C) if it’s too cold, or leave it to cool down if the fat is too warm. Once it’s at the right temperature, remove it from any heat source. Keeping the temperatures exactly right will help the fat and the lye to combine properly, resulting in a smoother soap and clearer glycerin.

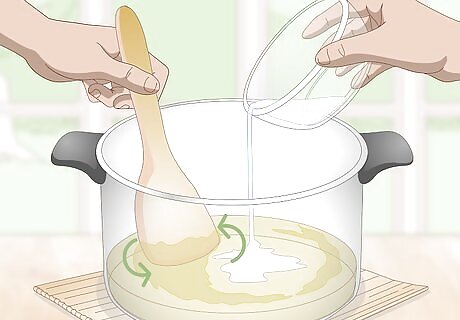

Pour the lye solution into the melted fat slowly, stirring constantly. With both the fat and the lye solution around 113 °F (45 °C), begin very slowly streaming the lye solution into the fat. Stir the solution in as you do, being careful not to splash the lye or get any on your skin. It may be easier to get someone to help you stir the fat while you pour in the lye. Work on a sturdy, flat surface so that you can continue stirring easily while the soap mixture thickens.

Mix the fat and lye together until the soap begins ‘tracing’. Once the lye solution has been completely mixed into the fat, keep stirring in slow, regular motions. After around 15 minutes, the path of the spoon should remain visible in the soap mixture for a few seconds. This is known as tracing and is a sign that your soap mixture has thickened and is ready. Rather than stirring by hand, you could use an electric mixer or a stick blender to combine the lye and fat. Start at a low speed to avoid splashing the mixture around too much.

Finishing the Glycerin

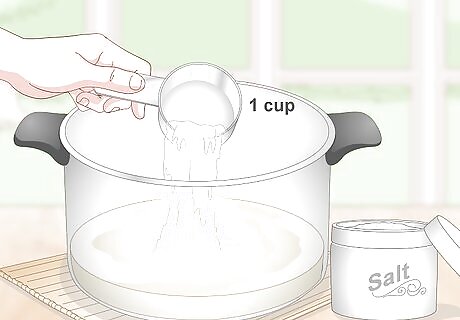

Add 1 cup (300 g) of salt to the soap mixture. Adding salt to the soap mixture will separate the soap from the glycerin. Measure out around 1 cup (300 g) of salt and slowly add it into your soap mixture, stirring constantly until it is combined. Use a standard and cheap table salt to separate the soap from the glycerin. Kosher salt or sea salt will be too coarse, as well as being considerably more expensive.

Leave the mixture to cool and curdle. Once the salt has been mixed in, the soap will begin to curdle and coagulate on top of the mixture. Let the mixture cool down for around 30 minutes to an hour. Make sure to remove your spoon or thermometer from the soap mixture before leaving it to set up.

Skim away the soap from the top of the mixture. When the mixture has cooled, the fat and lye should have coagulated into a soapy substance floating on top of a layer of glycerin. Use a slotted spoon to scoop away the soap and leave behind the pure glycerin. If you want to keep the soap, press it into a mold and leave it to dry for 3 to 4 days. Once dry, leave the soap to cure in a cool, dark, dry place, rotating it every day or two until completely solid.

Strain the remaining glycerin into a glass bottle to store. Place a fine-mesh sieve over a jug with a spout or something similar. Carefully pour the glycerin through the sieve to remove any lumps of soap, before transferring it to a glass bottle. Keep the glycerin in the refrigerator for up to a month. Once glycerin has expired, it will shift from being very clear to very cloudy. It may also develop a foul odor, at which point it should be discarded.

Comments

0 comment