views

Rust-Resistant Metals

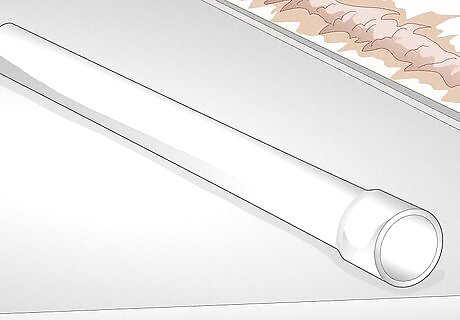

Choose stainless steel for the best protection against rust. Stainless steel contains a blend of iron, chromium, manganese, silicon, carbon, nickel, and molybdenum. These elements react with oxygen in the water and air to create a think layer that protects the metal from corrosion, so if you’re looking for the absolute best way to keep your metal from rusting underground, go with stainless steel. The chromium is the main metal that creates the protective film, and it also helps give it a distinctive shiny grey appearance. The only drawback is that stainless still is more expensive than other metals.

Go with aluminum for a cheaper alternative to stainless. Aluminum is fairly resistant to corrosion, so it’s a good material for you to choose to help prevent rust. It’s also much less expensive, making it a cost-effective metal for you to use for your underground projects. Aluminum’s affordability and rust-resistance are why it’s often chosen as a metal for outdoor projects like aluminum siding.

Use powder-coated metal to help prevent rust from forming. Powder-coated metal is metal coated with a mixture of resins, curatives, and other rust-prevention agents, which is then cured to form a protective coating that prevents rust and corrosion. Choose metal with a powder-coated surface for greater longevity and rust protection than standard steel. Powder-coated metal can be more expensive, but it’s much more durable and rust-resistant and can last for years.

Select galvanized metal for its sacrificial metal coating. Galvanized metal has been dipped into a metal such as zinc and magnesium to form a layer that protects the underlying metal from corrosion. If you’re using metal such as steel or iron, use a galvanized version to keep it from rusting underground. Steel can be protected from rust by placing a dissimilar metal like zinc or magnesium around it as a sacrificial layer.

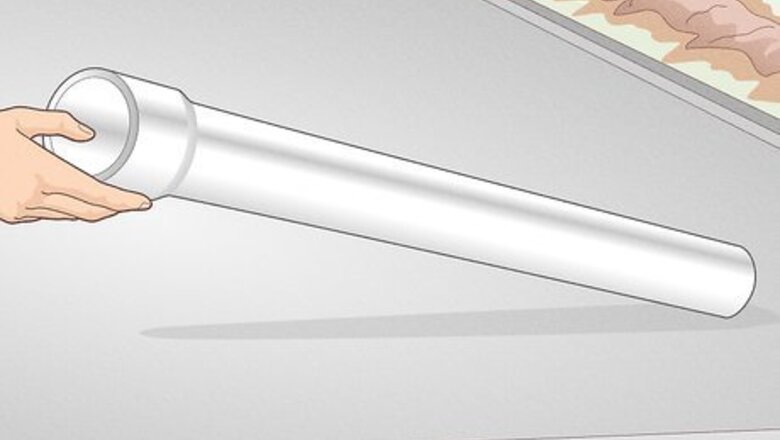

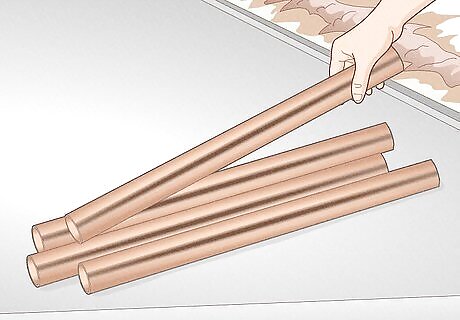

Pick copper for underground pipes and tubing. Copper is almost completely impervious to corrosion from most soils, but it will change color as it oxidizes (rusts). Choose copper water tubing as a metal that will reliably resist corrosion underground. Copper forms a protective layer as it oxidizes that keeps it protected from damaging corrosion.

Rust Prevention

Paint uncoated metal with primer for a cost-effective option. Choose an enamel, epoxy, or polyurethane primer that fits your budget and aesthetic. Use a paintbrush to apply an even coating over the entire surface of the unfinished or uncoated metal to seal it in a protective layer that will help prevent rust. Let the primer fully dry according to the recommendations on the packaging before you use it. Both enamel and polyurethane are great options, but polyurethane provides the best protection. Check your local environmental regulation for paint and coatings to make sure you choose a legal primer for your underground metal.

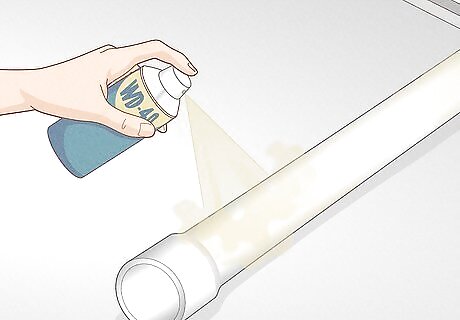

Spray on a commercial rust prevention product for a simple alternative. There are a variety of rust prevention products that form a protective layer over the surface of the metal. Spray the product onto the metal and let it dry according to the recommendation on the packaging for a simple way to help keep the metal protected from rust and corrosion underground. You can find rust prevention products at your local hardware store or home improvement store. You can also order them online. Popular products include Sta-Bil Rust Stopper, WD-40 Special Corrosive, and Permatex Rust Treatment.

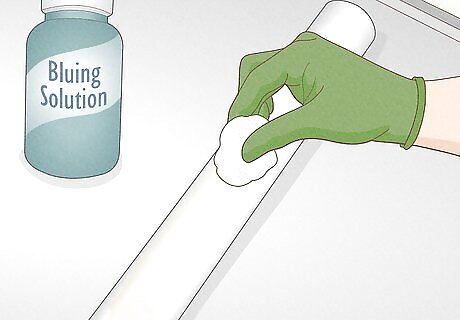

Try bluing the metal if you want to maintain the finish. Bluing steel is the process of oxidizing a metal surface, which forms a protective layer against rust. Clean the metal with alcohol, a grease remover, and then dry it off with a cloth. Apply a premixed bluing solution with a cotton ball or rag and then wipe it dry. Sand the metal to smooth out the finish and add any additional coats if you need to. If you want to keep the finish looking good while also protecting it from rust, bluing the metal is a solid option.

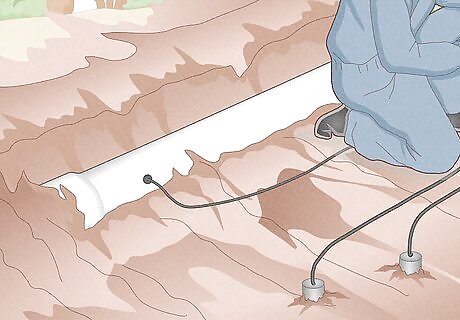

Install cathodic protection to protect against leaks and spills. Choose cathodic protection to protect underground pipelines and buried steel tanks from corrosion that could cause the contents to spill out into the environment. Search online for an installation company that can install cathodic protection, which uses an electrical current to prevent rust and corrosion from forming on metal underground. Cathodic protection is usually used for underground pipelines and buried steel tanks, and it requires careful engineering that needs to be done by a professional. If it’s installed improperly, the electrical current could actually make corrosion worse.

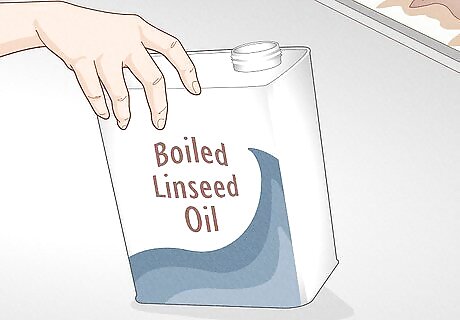

Boiled Linseed Oil (BLO)

Choose BLO to protect unfinished metal or cast iron. Boiled linseed oil (BLO) is a great natural product that you can use to form a protective layer that will help protect metal against corrosion. Choose it as a natural alternative for unfinished or uncoated metal like cast iron to help keep it from rusting.

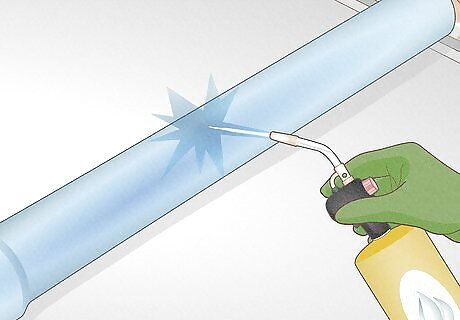

Use a blowtorch to heat the metal until it turns blue. Wear protective gear including goggles and gloves and turn on your blowtorch. Move the flame back and forth over the surface of the metal to heat it evenly. Continue heating the metal until it starts to glow a soft blue color. Heating the metal helps it absorb the oil and form a protective layer. Be sure to work in a well-ventilated room as well to avoid breathing in any toxic fumes.

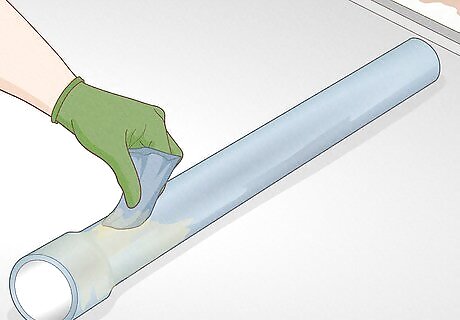

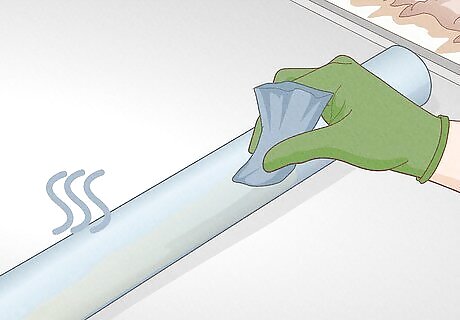

Apply a coat of BLO with a clean cloth. Take a clean cloth, such as a blue shop towel, and add some of the boiled linseed oil to it. Wipe the oil all over the surface of the metal to spread an even layer. The metal will be hot so keep the cloth moving so it doesn’t singe or burn. Coat both sides of the metal.

Let the metal dry and then apply another coat. Wait a few minutes until the surface of the metal is no longer visibly damp. Take your cloth and add some more oil to it. Wipe it over the surface of the metal to apply another even coating of the oil. Leave the metal to dry and lock in the oil to form a protective layer. Be careful not to touch the metal until it’s fully cooled! You may want to hang the metal from a hook so it can safely cool down.

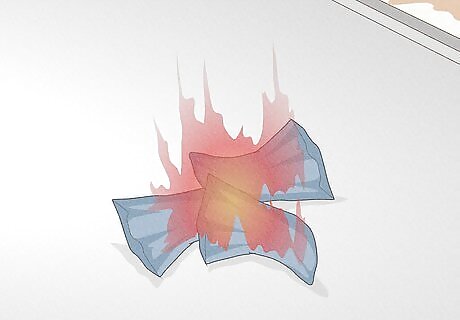

Allow the cloth to dry or burn it to dispose of it. Cloths soaked in linseed oil can spontaneously combust and catch fire. Don’t leave them scrunched up and lying around when you’re finished. Instead, either safely burn the cloth when you’re finished or hang it up outside until it’s dry and then dispose of it. Avoid moving the BLO-soaked cloth in the blowtorch flame as well.

Comments

0 comment