views

Preparation

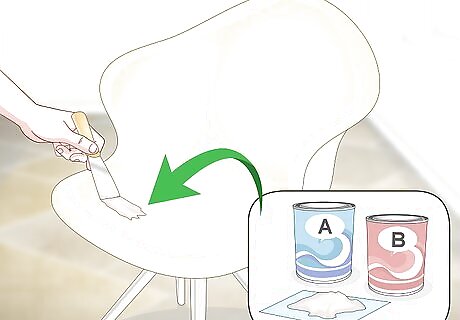

Fill in any cracks or gouges in the fiberglass with polyester filler, marine grade. Epoxy filler, although a great product is not suitable for a gel-cote top coat. Polyester gel-cotes will not chemically bond to epoxy. You’ll want to take care of any damage on the fiberglass first so you have a smooth surface to apply the gelcoat to. To fill in damaged areas, start by sanding them with coarse 36 grit sandpaper to remove any debris. Then, fill in the damaged areas with the polyester filler using a plastic spreader. Let the polyester filler cure until material is firm and tack free, about 10 minutes. Sand it down with 80 grit sandpaper until it’s flush with the surface of the fiberglass.

Clean the fiberglass surface with ajax or comet and water. It’s important that the fiberglass is clean before you gelcoat over it. If there’s any dirt or dust on the fiberglass, it will get trapped under the gelcoat. Go over the fiberglass with a soapy rag and then wipe it down with a clean rag to remove any leftover suds. If you’re cleaning a large fiberglass surface, like the hull of a boat, use a power washer to make the process easier and faster, be very careful, as a power washer can actually cut fiberglass and blow chunks right off surface.

Wipe the fiberglass down with acetone to remove grease and wax. This step is especially important if you’re gel-coating old fiberglass that already has a coating on it. Removing any grease or wax on the fiberglass will help the gelcoat adhere better to the material’s surface. Once you’ve gone over the whole surface with a rag soaked in acetone, and immediately removing it while still wet with a second dry rag.

Application

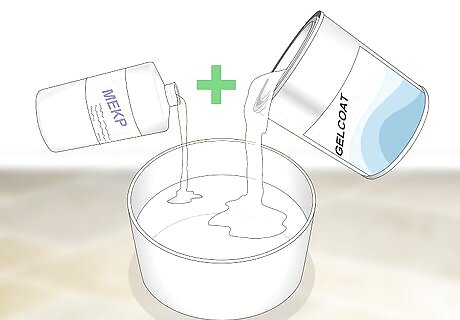

Combine gelcoat and methyl ethyl ketone peroxide in a bucket. Methyl ethyl ketone peroxide (MEKP) is a catalyst used to make gelcoat start to harden. You’ll need to buy a container of MEKP separately if it doesn’t come with your gelcoat. Refer to the manufacturer’s instructions on the side of the gelcoat can to see how much MEKP you need to mix with the gelcoat. The amount of MEKP you’ll need to use will depend on how much gelcoat you’re using and what brand it is. Make sure you follow the manufacturer’s instructions so the gelcoat isn’t the wrong consistency.

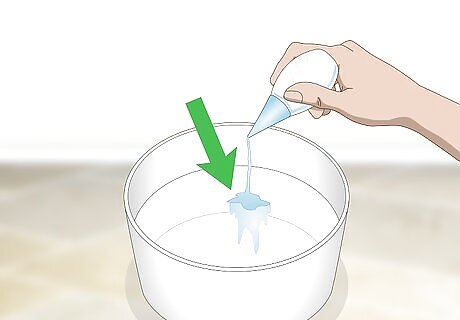

Add gelcoat color pigments if you want your gelcoat to be colored. If you want the gelcoat to be a different color than white, you'll need to add color pigments. Buy gelcoat color pigments that match the color you’re looking for and follow the manufacturer’s instructions to mix the pigments into the gelcoat.

Apply the gelcoat using a brush if you’re covering a small area. To apply the gelcoat with a brush, dip the brush in the gelcoat so there’s a liberal amount of gelcoat on it. Brush the gelcoat onto the fiberglass using short vertical strokes. Avoid spreading the gelcoat too thin or you’ll get stroke marks. You want there to be a thick, even layer of gelcoat on the fiberglass. When you’re finished, you shouldn’t be able to see any of the fiberglass underneath the gelcoat.

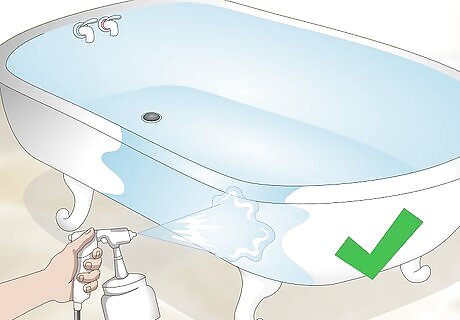

Apply the gelcoat with a gelcoat spray gun if it’s a large fiberglass surface. A gelcoat spray gun will make it easier to get an even coverage on a large fiberglass surface. To use a gelcoat spray gun, fill the plastic container on the gun with your gelcoat. Then, attach the cord on the gun to an air supply source, like an air compressor. Hold the spray gun about 1 foot (0.30 m) away from the fiberglass and spray the gelcoat onto it in short, even strokes. You can buy a gelcoat spray gun online or at your local paint store.

Let the first coat of gelcoat dry for 4 hours and then check on it. The first coat should feel tacky when you touch it. Try pressing into the gelcoat with your fingernail — if it doesn’t leave an impression, the gelcoat is dry enough. If your fingernail does leave an impression, let the gelcoat dry for a couple more hours.

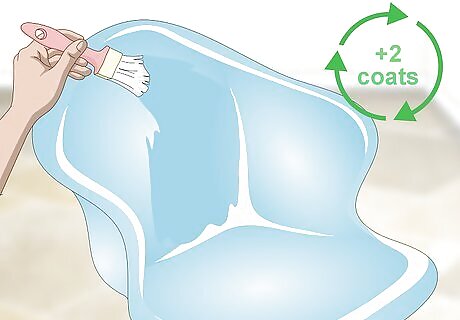

Apply 2 more coats of gelcoat to the fiberglass. Three coats should be enough, but you can do more coats if you’re not satisfied with the final result. Let the second coat dry for 4 hours like you did with the first coat. For the final cote add sanding aid.. A mixture of styrene and gulf wax, to the gel-cote and add MEKP as before. This may be purchased at the same place you bought the gel-cote. It is important to note that gelcoat is air inhibited, meaning that it will not fully cure in the presence of oxygen. The wax migrates to the surface of the final coat and creates a barrier to allow the gel to cure.

Finishing

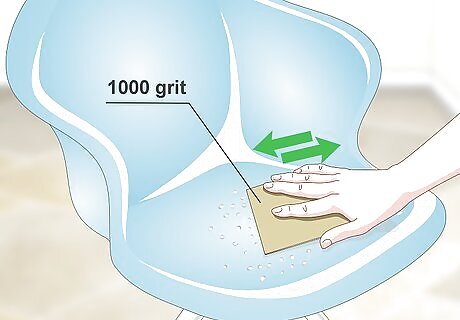

Sand the surface of the fiberglass with 1,000 grit sandpaper. Sanding the fiberglass will help smooth out any rough spots in the gelcoat. If you’re sanding a large fiberglass surface, like the hull of a boat, use a random orbit sander to speed up the process. When you’re done sanding, wipe away any dust with a dry rag.

Apply rubbing compound to the fiberglass with a cloth. Rubbing compound contains small particles in it that help buff out a surface and make it smoother and shinier. Buff the compound into the fiberglass surface in a circular motion until the compound fades. If you’re working with a large section of fiberglass, use an electric buffer to apply the rubbing compound.

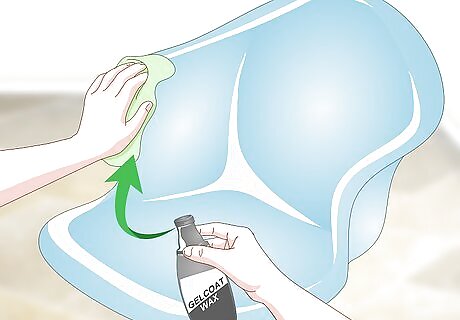

Apply a wax over the gelcoat to protect it. Wax will also make the gelcoat shinier and more reflective. Use a wax designed specifically for gelcoat or fiberglass. Use a cloth to apply enough wax to the fiberglass that there's a thin, visible layer over the entire surface. When the wax dries, buff it off with another cloth.

Comments

0 comment