views

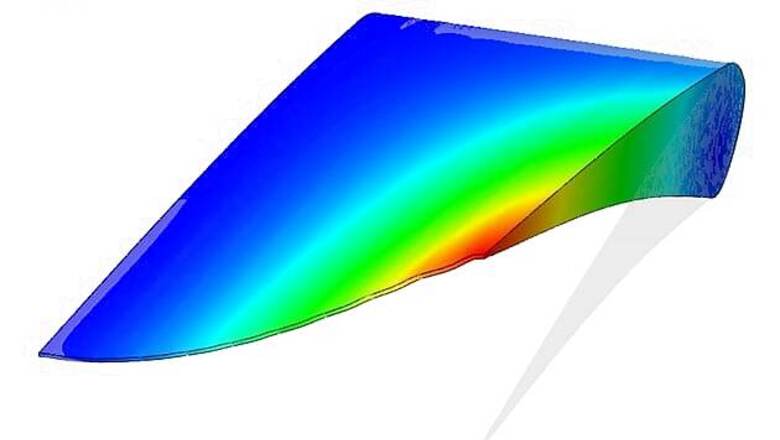

Berlin: Researchers are developing next-generation wing flaps for airplanes that can change shape like a bird's wing for greater efficiency.

The Europe's Smart Intelligent Aircraft Structures (SARISTU) programme aims to reduce kerosene consumption by six per cent, and integrating flexible landing devices into aircraft wings is one step towards that target.

Airport congestion has reached staggering levels as some 2.2 billion people a year take to the skies for business or pleasure, researchers said.

As their numbers grow and more jets add to pollution in the atmosphere, the drawbacks to the popularity of flying become obvious, they said.

While birds are able to position their feathers to suit the airflow, aircraft wing components have so far only been rigid.

"Landing flaps should one day be able to adjust to the air flow and so enhance the aerodynamics of the aircraft," said Martin Schuller, researcher at the Fraunhofer Institute for Electronic Nano Systems ENAS in Chemnitz.

A mechanism that alters the landing flap's shape to dynamically accommodate the airflow has already been developed by the consortium partners.

Algorithms to control the required shape modifications in flight were programmed by ENAS, in collaboration with colleagues from the Italian Aerospace Research Center (CIRA) and the University of Naples.

The mechanism that allows the landing flap to change shape can only function if the skin of the landing flap can be stretched as it moves, a problem tackled by researchers from the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM in Bremen.

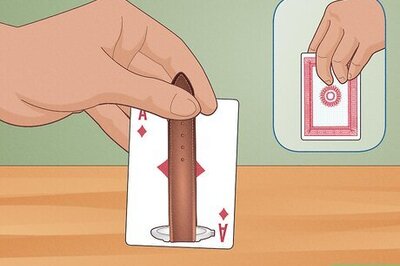

"We've come up with a silicon skin with alternate rigid and soft zones," said Andreas Luhring from Fraunhofer IFAM.

"There are five hard and three soft zones, enclosed within a silicon skin cover extending over the top," said Luhring.

The mechanism sits underneath the soft zones, the areas that are most distended.

While the novel design is noteworthy, it is the material itself that stands out, since the flexible parts are made of elastomeric foam that retain their elasticity even at temperatures ranging from minus 55 to 80 degrees Celsius.

Four 90-centimetre-long prototypes two of which feature skin segments are already undergoing testing.

Comments

0 comment