views

Replacing a License Plate

Examine the bolts holding the license plate to see what tools you need. Depending what kind of bolts are holding it in place, you may need a wrench, a flathead screwdriver, or a Phillips head screwdriver. Once you have the correct tool, make sure it is the right size and fits snuggly on the bolt so that you don’t strip it. It may be possible to remove some bolts with multiple methods, for example a hex head bolt may also have a slot for a flathead screwdriver.

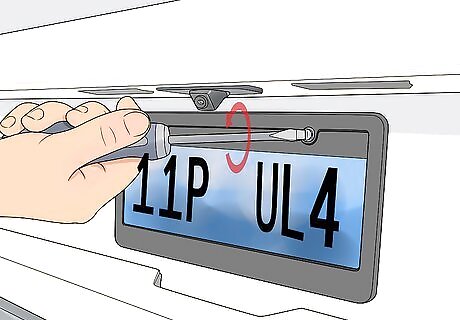

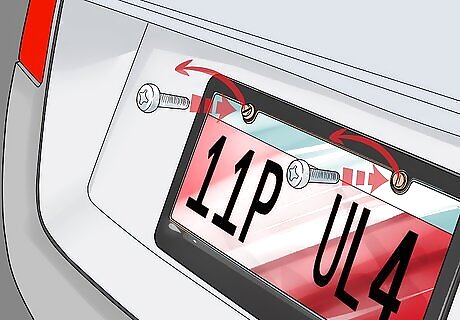

Unscrew the license plate bolts by turning them to the left. Attach your wrench or screwdriver to the bolt and turn the tool in a counterclockwise motion until the bolt comes completely lose. Set aside the bolts that you removed in a safe place so that you don’t lose them. Start with removing either both the top two or bottom two bolts, then stabilize the license plate with one hand, or have someone hold it for you, while you remove the last two bolts so it doesn’t fall and scratch any paint on your car.

Remove the license plate and set it aside. Once you have removed all of the bolts you can take the old license plate off and save it. If you just want to get rid of the license plate you should recycle it instead of just throwing it in the trash. There are lots of cool ideas online to make old license plates into art if you want to give it new life!

Put the new license plate into place and attach it using new bolts. Your new license plate should come with bolts to attach it. Hold it in place with the holes aligned or have someone help you out to keep it steady while you screw the new bolts in. It’s a good idea to use stainless steel bolts to avoid rust problems in the future! Make sure to put any new registration tabs on the new license plates, and always keep the appropriate registration documents in your car.

Removing Rusted License Plate Bolts

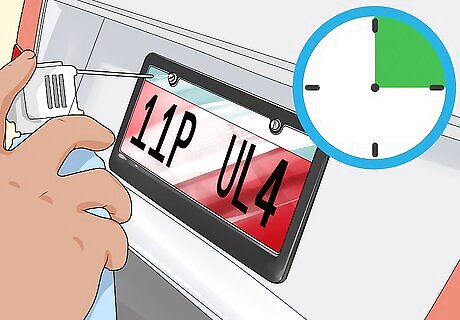

Spray any rusted bolts with penetrating oil and let them sit for 15 minutes. Get as close to the rusted bolts as you can with the nozzle of the spray can. Thoroughly douse all exposed parts of the bolts in penetrating oil. After 15 minutes try to unscrew the bolts. If the bolts still don't come loose after letting the oil sit for 15 minutes, spray on more and let them sit for an hour. You can get penetrating oil at an automotive repair shop. If you can, spray behind the license plate to reach the back of the bolts, do this as well. You want to give the oil as much contact with the bolts as possible. Deanna Sclar Deanna Sclar, Auto Mechanic Educator Spray penetrating oil generously on rusted bolts and let it soak in fully. Test loosening each bolt gently before applying full force—never twist severely degraded fasteners. If standard wrenches slip on rounded edges, use a six-point socket for better grip. Employ long extensions when necessary for optimum leverage and control. With quality chemicals, the right specialty tools, and patience, removing seized hardware can be satisfying rather than frustrating, deepening your vehicular bond.

Try soaking the rusted bolts with white vinegar. Pour white vinegar over the rusted bolts or soak a cloth with vinegar and hold it over the bolts. The acidity of vinegar will dissolve the rust. Once you get some of the rust off, try removing the bolts with a wrench or screwdriver. After you have dissolved some of the rust with vinegar, you can try to scrub off as much of the rust as you can with steel wool or a steel brush before attempting to loosen the bolts.

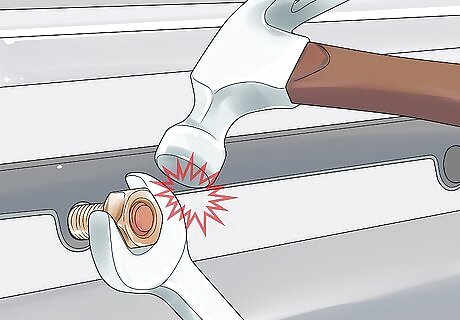

Attempt to loosen the bolts by hitting a wrench with a hammer. Attach the wrench to the bolt in a tightening position and hit it on the end of the handle twice with a hammer to deliver a shock and break the rust. Adjust the wrench to a loosening position and try to unscrew the bolts. You don’t want to actually tighten the bolt, so if this doesn’t work the first time don’t keep hitting the wrench in the tightening position.

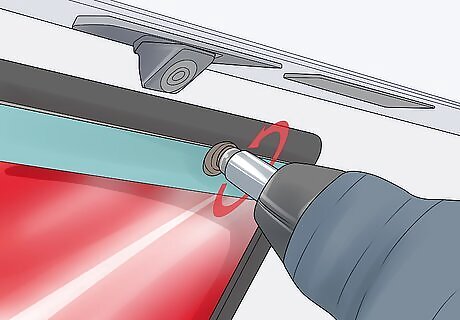

Use an impact wrench if you have one to break the bolt free of the rust. An impact wrench is a powered wrench that you can use as a last resort if the bolts won’t come loose. Choose the correct impact socket, attach it to the bolt, and pull the trigger of the impact wrench to exert force on the bolt. Use safety glasses and gloves when you operate an impact wrench. This method may just simply break the rusted bolts, so use it once you have exhausted all other options.

Replace the rusted bolts with stainless steel ones. Once you have successfully removed the bolts, replace them with stainless steel ones to avoid problems with rust in the future. You can also coat the threads of the bolts with anti-seize lubricant to make it even easier next time you want to remove the plate. You can find anti-seize lubricant at an auto repair shop.

Comments

0 comment