views

Building a Plastic or Foam Board

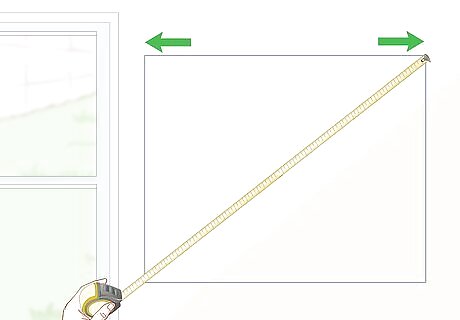

Size the board according to the amount of space available. The size of your makeshift board is completely up to you. However, measure out your available wall space ahead of time so you know what size of material to order. Use a tape measure to plan out where you intend on hanging your new board. Write the dimensions down and take them with you to the store. Most whiteboard materials come in 4 ft × 8 ft (1.2 m × 2.4 m) sheets, although there are other sizes available. If you can't find the size you need, you can usually order it at a home improvement store.

Purchase a melamine sheet for a classic white-colored board. Melamine is a fiberboard sheet that has a hard coating on one side. Most store-bought whiteboards are made with melamine, so you know what to expect when you use it in your project. Some sheets are textured to look like tile, which can be useful if you need to organize information into squares, but usually a smooth sheet is a better choice. Smoother sheets are easier to erase and look better when written on. Porcelain is a similar option. It actually is more durable than melamine, but that means it is also more expensive.

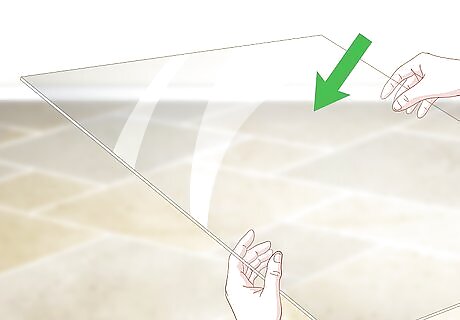

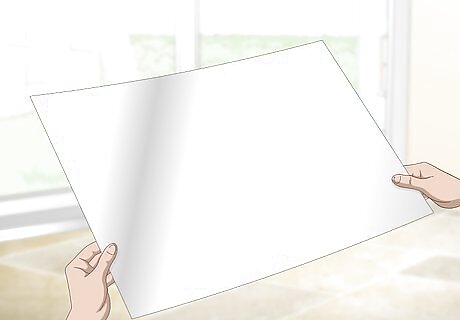

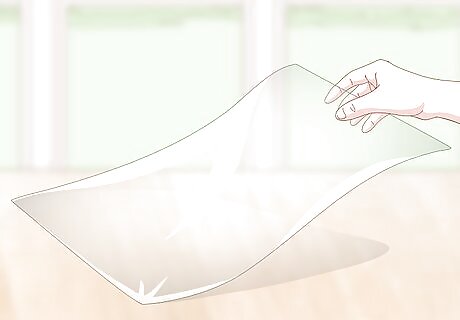

Get a plastic sheet if you're planning on making a clear board. Try plexiglass or Lexan to make something unique. Acrylic and polycarbonate sheets are transparent, allowing you to see the wall behind them. When you write on the board, it is like writing on the wall. Of these materials, Lexan is preferable since it's about half as thick as plexiglass, weighs less, and doesn't shatter if you need to drill it to hang it on the wall. Plastic boards don't stand out as much in most rooms and go well on white walls. You can also get a big sheet of plastic to make a massive board to write all over. The board is very easy to clean and last longer than melamine.

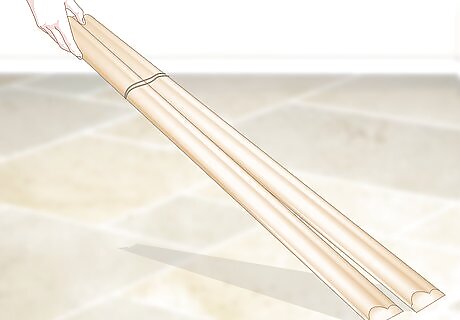

Purchase wood trim to build a frame for the board. Pick lengths of molding that are longer than the board so you can cut them to create a picture frame. A pair of 8 ft (2.4 m) pieces is perfect for a 2 ft × 4 ft (0.61 m × 1.22 m) board, for instance. The frame hides the unfinished edges of the board, gives it a pleasing border, and often makes it easier to hang. Use wood molding or furring strips for an easy way to fashion a frame. Store-bought molding is a little costly compared to the rest of the material you use. If you're looking to save money, try repurposing some wood scraps you have lying around.

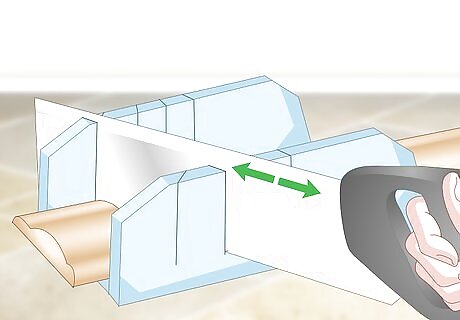

Measure and cut the wood trim using a miter box. Use a tape measure to determine the length and height of your whiteboard. Measure and mark these distances in pencil on the wood you plan on using for the frame. Then, fit the wood into the miter box, lining up the marks with the grooves for the saw. Slide a basic hand saw into the grooves to cut the wood at a 45-degree angle. To check the fit, push the wood pieces together. When they are cut correctly, they fit together like any picture frame. Redo the cuts if you notice any gaps or overlap in the frame. If you have a circular saw, you could use that instead to cut through the wood more quickly.

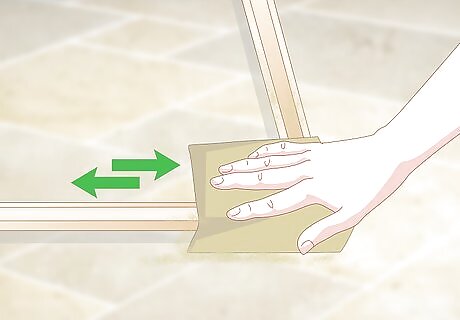

Sand the wood with 120 and 220-grit sandpaper if you are staining it. Sanding the wood helps the stain adhere to the frame pieces. Start with the 120-grit sandpaper and use light but firm pressure to it along the wood's grain. Then, shift to the 220-grit sandpaper and go over the frame again to smooth it out. The grain is the visible fibers in the wood. Follow the lines to avoid leaving some unpleasant scratches on the wood.

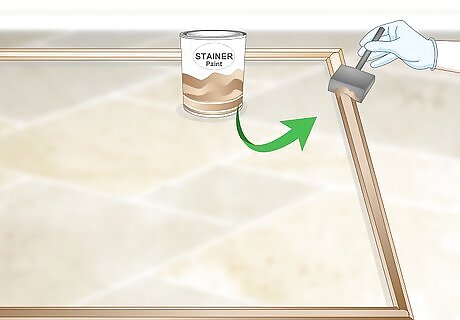

Spread a staining product onto the wood to give it more color. Choose your stainer, then use a foam brush to spread it along the wood's grain. Go all the way across the wood with single, continuous strokes. When you're done, let the stain set for up to 15 minutes before adding another coating. Additional coats darken the wood, making it look much more appealing after you hang it on a wall. Wear gloves when applying a stainer. If you add too much of it, mop up the excess with a rag before it sets into the wood.

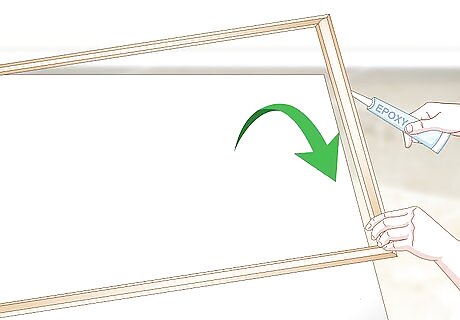

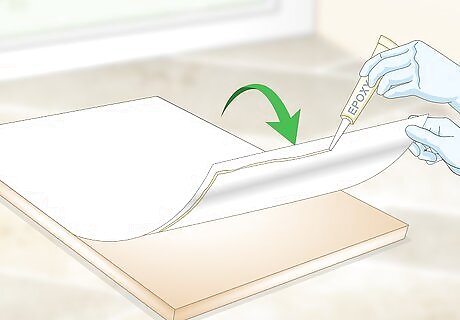

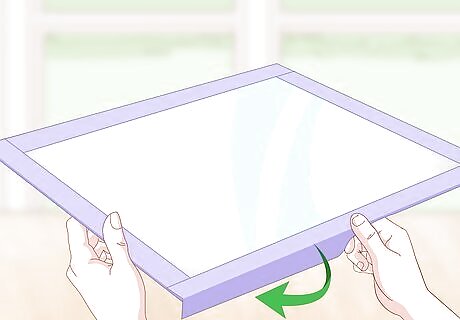

Glue the wood to the board using a clear epoxy. Make sure the frame fits well over the edges of the board before gluing them in place. When you're ready to add them, spread the glue across the backs of the framing boards. Set the frames down on top of the edges of the whiteboard, clamping them down if needed to hold them in place. Also, add glue to the edges of the frame boards where they connect to help stick them together. Epoxy glue often comes in 2 parts. You have to mix an equal amount of the resin and hardener to create the glue. Some other glues to try include an acrylic polymer and super glue. A polyurethane construction adhesive is great for sticking foam boards to wood since the foam resists most other types of glue.

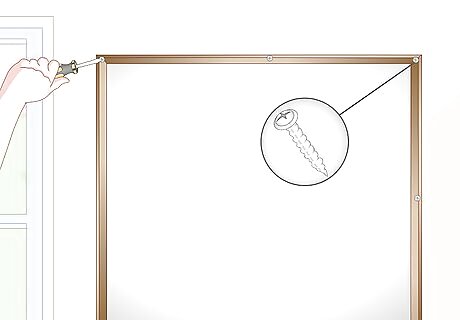

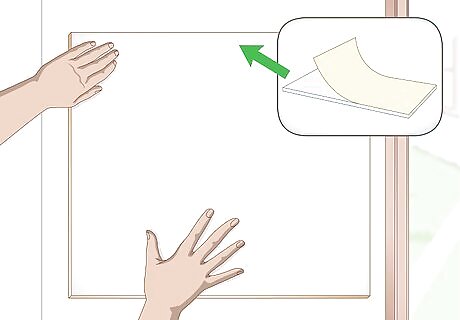

Hang the board by screwing it onto the wall. Measure every 12 in (30 cm) along the frame. Using a cordless screwdriver, install 2 in (5.1 cm) drywall screws directly through the wood and into the wall. Have someone hold the frame in place the entire time. The screws need to be positioned on the wood supports, or studs, in the wall so your whiteboard doesn't end up crashing to the ground. To locate the support beams in the wall, use a wall stud finder. When you drag it along the wall, it lights up as it detects the beams. Mark these spots so you know where to position the board for maximum security.

Creating a Magnetic Metal Board

Buy a sheet of metal the size you want the board to be. When you're making a whiteboard, go with something thin and durable. Metal is perfect for this task. Get a galvanized steel sheet if you're looking for something magnetic. With steel, you can pin magnets to it in addition to drawing on it. Note that while aluminum might seem like a good choice because it's lighter than steel, it isn't magnetic.

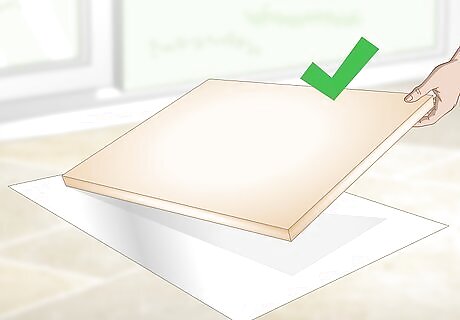

Use a wood sheet to back and strengthen the board. Many whiteboards aren't a single piece of uniform material. Add a back to your metal board in order to make it easier to move around and hang up. Cork is a great choice since it is soft and lightweight, but you could use plywood or something similar. Try to get backing the same size as the board you wish to make. If you can match it to the size of the metal, then you don't have to do any additional trimming. If the backing is too big, you can cut it with a basic hand saw. However, most home improvement stores will cut the board to size if you ask them to do it when you make your purchase.

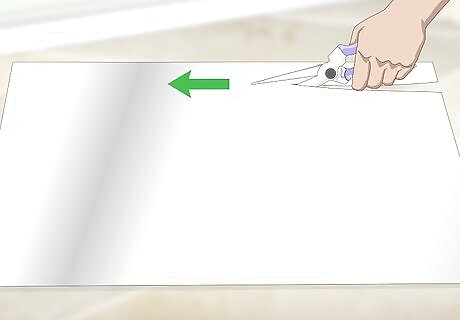

Use tin snips to trim the metal to size if needed. It all depends on how big you want the board to be and how much space you have for it. If you aren't able to leave the metal sheet as is, get a pair of straight-cutting tin snips. Cut carefully around the metal to reduce its size so it fits over the backing you chose. Cut metal is sharp. Be careful to avoid touching it, and consider wearing leather gloves for protection. There are different types of tin snips, so pick ones with yellow handles. This kind is best for cutting straight lines, which is all you really need to do to make your board.

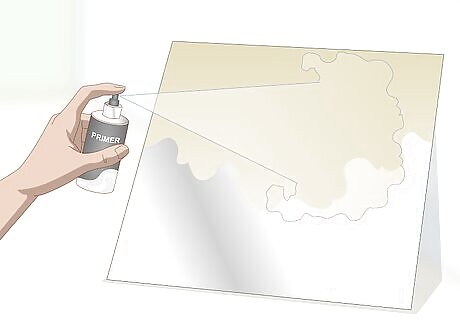

Spray a primer on the metal if you plan on painting it. While there are no rules saying that you have to make your board white, they are traditionally painted this way to make all colors of ink visible. To begin painting your board, get a rust-resistant latex primer. Spray back and forth along the metal sheet in a single, controlled motion. Keep the spray can about 6 in (15 cm) above the metal at all times. Before priming, wipe off any dirt you notice on the metal. Use a soft cloth dampened in water. Using white vinegar or mineral spirits also helps ensure your board is clean and ready for painting. To get a nice, even coating, make a second pass after allowing the initial layer to dry for about 15 minutes. Dry erase markers work very well on bare metal, so you don't have to paint your board at all if you don't want to. If you like the look of shiny metal more than the traditional white of store-bought boards, leave it as is. Keep in mind that darker markers will be a little harder to spot, though.

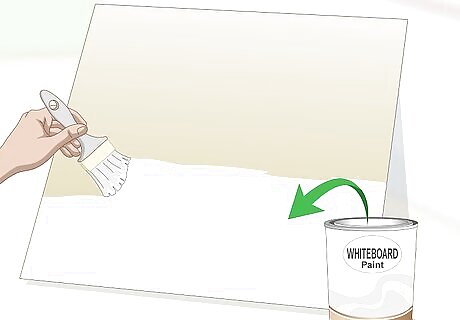

Color the metal white using whiteboard paint. Be sure to note the mixing instructions on the paint can. Mix the actual paint with a liquid activator included with it, then let it settle for about 1 hour. Afterward, spread the paint across the metal using a foam roller. Try to make the surface as smooth and even as possible so you don't leave any rough spots that are difficult to write on. A whiteboard is all about smoothness and consistency. Dry erase markers don't show up well on rough surfaces, so take all the time you need to get the paint right.

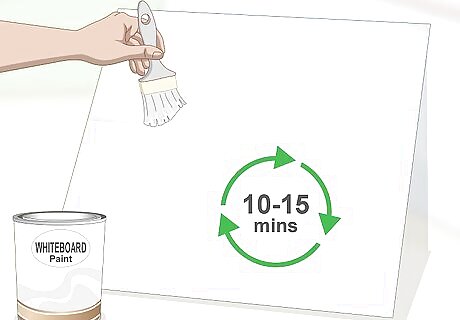

Wait 10 to 15 minutes before adding additional layers of paint. The whiteboard surface probably won't look the way you want after the first coating. Roll an extra layer of paint over it to ensure that your board is thick enough to draw on. Since metal is dark, consider applying 3 or 4 total layers. Wait a little bit between each layer to allow the paint to dry. Give the metal an even coating of paint. Keep rolling additional coats onto it until you're happy with the way it looks.

Glue the painted metal to the backing using epoxy. Epoxy is pretty harsh, so put on a pair of rubber gloves before using it. Mix the epoxy using something disposable, such as a wooden paint stick. When you're ready to use it, spread it immediately over the backing in a thick, consistent layer like you're frosting a cake. Then, set the metal on top of it, painted side up. You could also use a polyurethane-based super glue or a silicone construction adhesive to hold your board together.

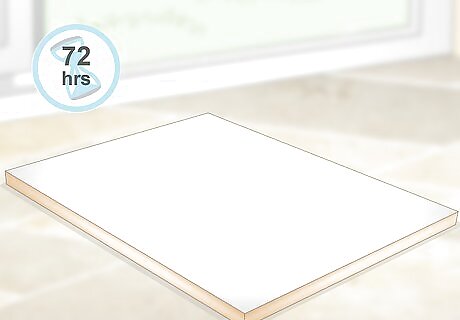

Wait 72 hours for the paint and glue to cure. Your board won't even be useable yet, so you might as well give it plenty of time to dry. Once the glue settles, you can hang your board without worrying about a big sheet of metal crashing to the floor. Don't write on the board until it has had a chance to dry.

Hang the board using sticky picture-hanging strips. Peel the paper backing off the strips, then set 1 on each corner of the back of the whiteboard. The other side of the strips are also sticky, so push the whiteboard firmly against the wall. Press firmly on the whiteboard for about 30 seconds to hold the strips in place. Test out your new whiteboard when you're done. Picture-hanging strips are the only way to hang the whiteboard without drilling holes through it or the wall. If you're planning on hanging the board on your refrigerator, use some glue to stick magnets in the corners. Use epoxy, super glue, or another strong, durable adhesive. Another option is to screw the board to the wall. You could also buy a metal picture hanger that attaches to drywall to hang the board.

Making Small Paper Boards

Purchase plastic covers or wraps to use as a whiteboard. When you're looking for something to write on over and over again, nothing is better than plastic. Report covers (plastic sheets that sheathe important papers) are an inexpensive option. The average cover is about 8 ⁄2 in × 11 in (22 cm × 28 cm) in size, making it perfect for small, individual whiteboards. You might be able to find some different sizes, depending on where you look. Report covers look almost like plastic folders or binders. You could get individual plastic sheets, but most covers come in pairs held together by plastic bars that slide off. You can get report covers at most general stores and office supply stores, along with any other supplies you need, if you don't have them already.

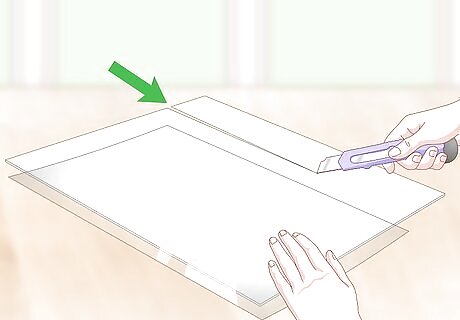

Trim a piece of white card stock to the same size as the cover. Card stock is great for creating a solid base to write on, but you could also use paper. Since report covers are meant to contain paper, you usually do not need to trim it. Card stock is a little different, so cut it to fit in order to get a stronger whiteboard. Paper whiteboards are not as strong as card stock ones, but you can always swap out the paper. It's really useful for students, for instance. You could put in a math worksheet, then swap it out later for something else.

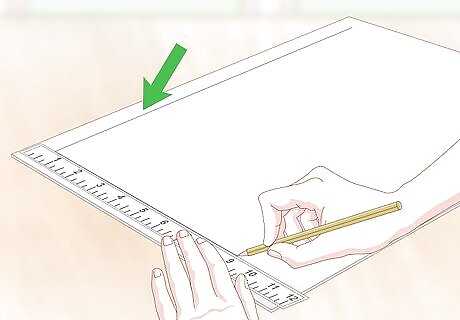

Measure and mark any borders you plan on adding to the sheets. Add a tape border to hold the plastic sheets together and make them more pleasant to look at. Choose a colorful roll of duct tape, then measure its width and divide the number by 2. Trace that measurement around the edges of the plastic using a washable marker. The tape needs to wrap around the edges of the plastic. Half of it will be on the front plastic cover and the other half will be on the back. Outline your border accordingly.

Place the tape on the cover to hold the plastic together. Wrap the tape over the edges of the plastic to hold the covers together. Smooth it out to get your completed whiteboard. Plan on leaving at least 1 side of the plastic open if you intend on swapping out the paper between it. For a permanent whiteboard where you won't remove the card stock, tape up all 4 sides. Remember to put the card stock in before you close up the last side. Another way to do this is to wrap plastic around card stock. You could get a sticky plastic film or glue plastic with a transparent decoupage glue. You could also get a piece of card stock laminated to create a strong whiteboard with a clear cover. If you don't have a laminating machine available, check your local library.

Comments

0 comment