views

X

Research source

You can make a vacuum pump to seal packages or even do science experiments. The simplest methods for creating vacuum pumps include using a syringe with tubing and reversing the disc on a bicycle pump.

- Burn a hole into a syringe using a hot knife, then screw a valve into that hole.

- Cut a piece of plastic tubing and fit it over the top of the syringe. Then, insert the non-threaded side of another valve into the tubing.

- Finish by attaching tubing of any length to the threaded end of the valve you inserted.

Building a Pump from a Syringe & Tubing

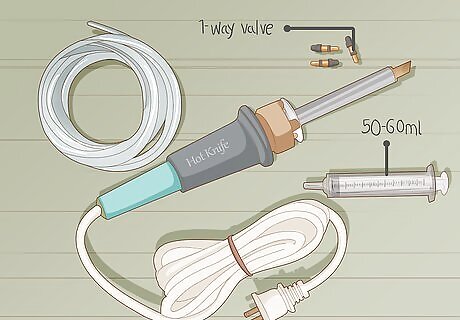

Pick out a syringe, 3 1-way valves, a hot knife, and tubing. Select 3 small 1-way valves used for bicycle tires and pick out a hot knife with a tip that matches the size of the valves. Also, get a 50-60mL needleless syringe and 12 inches (30 cm) or so of plastic tubing that matches the size of the valve. Some valves are 6 millimeters while others are 8 millimeters. Either kind is fine, but your plastic tubing should match. Find these syringes at most drug stores. Pick the kind that doesn't have a needle coming out. Look for hot knives at craft stores or home improvement stores.

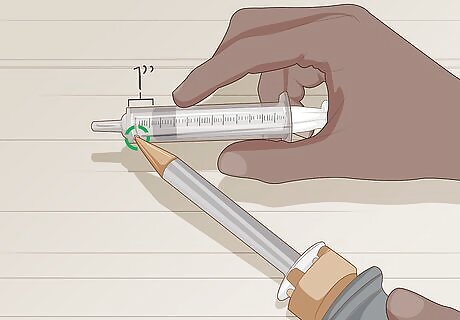

Burn a hole in the side of the syringe. Change the tip on the hot knife to the round tip that's the same size as your valves. Plug the knife in to heat up. Gently pull the plunger back on the syringe about 1 inch (2.5 cm). When the knife is hot, plunge it into the side of the syringe, making a hole in the space you've created by moving the plunger. The exact spot doesn't matter, but place it closer to the tip edge of the syringe than the plunger end. Try to keep the hole as small as possible, as you want the valve to fit in the syringe tightly.

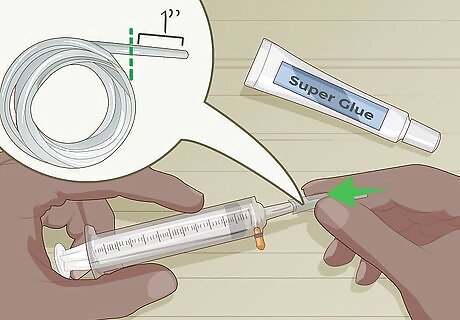

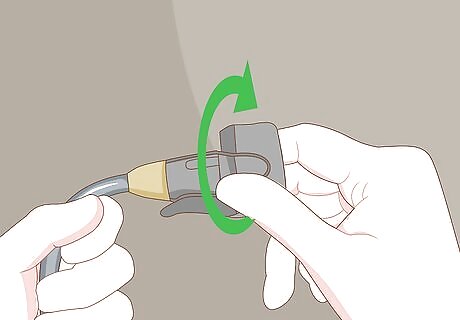

Screw the valve into the hole you've just made. Unscrew the black cap off the top of the valve. Turn the threaded part of the valve into the hole. Keep turning it to the right (clockwise) until the valve is as far as it will go in the hole. You'll still have the top part of the valve sticking out of the syringe. At this point, it can help to squeeze a little superglue around the valve, as that will help seal the pump.

Cut a 1 in (2.5 cm) piece of plastic tubing and slip it on the syringe. The length doesn't need to be exact. After you cut it, wedge it onto the tip of the syringe so it fits over it tightly. It can help to add a dollop of superglue around the edges to keep it in place.

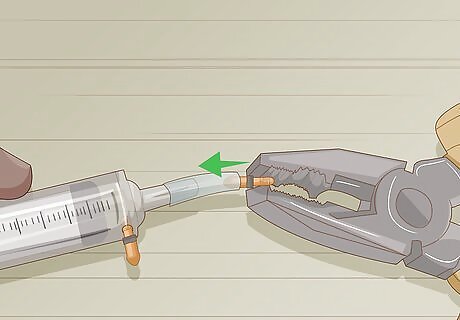

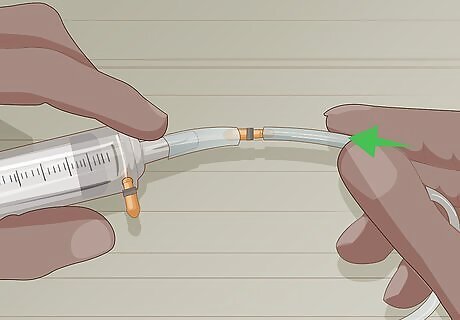

Press the non-threaded side of another valve into the tubing. Push it in as far as it will go. It will eventually hit the lip, and when it does, stop there. You may need to use pliers to help work the valve into the tubing. Some people skip the tubing altogether and just press the valve into the end of the syringe's tip. You can test both options to see which works best for you.

Attach tubing to the threaded end of the valve. Use any length of tubing but make sure it's long enough to reach your pressure chamber. Once it's threaded onto the tubing, attach it to a valve on your pressure chamber to complete the pump. A simple way to make a pressure chamber for your vacuum pump is to drill a hole on the top of a canning jar and insert a bicycle valve thread-side down into the hole. Seal the edges with silicone gel or superglue. To use the vacuum, start with the plunger of the syringe nearly all the way in and then pull it out to the end of the syringe to create a vacuum.

Creating a Pump from a Bicycle Pump

Take the top part of the bicycle pump off. Typically, you'll just need to find the screws holding it in place. In fact, it may only have 1 screw. Use a screwdriver to take the screw out, then pull the inside parts of the pump out so you can see them.

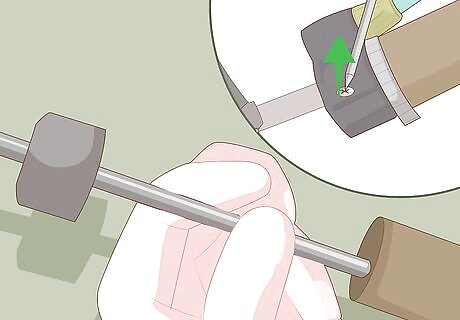

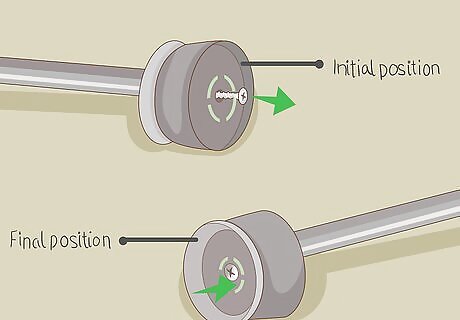

Turn the packing around the piston rod to the opposite side. When you open the bicycle pump, the rod is on the inside so as soon as you pull the parts out, you'll see it. When you pull out the rod, you should see a small disc on the other end. That's what makes the vacuum in the tube. However, instead of blowing air, you need to pull it. The packing should make a u-shape facing down when you pull it out. Take it off by unscrewing the part at the bottom of the disc and turn it so it's facing up instead. Screw the bottom back in place. If yours doesn't seem to have this component, another option is to carefully unscrew the disc and flip it around to screw it back on. If the hole doesn't go all the way through the disc, you can drill through it using a bit of the same size.

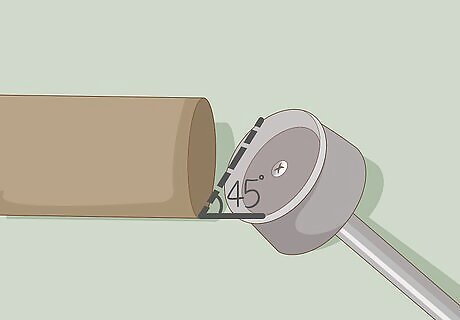

Put the rod back into the cylinder. Gently line up the disc with the inside of the rod. Go in at a 45-degree angle at first as you push it in so you have less resistance from the tube. Push it all the way back into the cylinder, lining it up straight as you get further down. Go slowly if you need to as you don't want to damage the bicycle pump or the disc in the process.

Unscrew the head of the tube that would normally lead to the bike tire. Follow the tube to the end to find the head. Use your fingers to unscrew it. If it doesn't unscrew easily, cut the head off instead by slicing through the tubing just below it. Try to make an even cut on the tubing so it will attach to the vacuum chamber better. Once it's cut, the vacuum pump is done.

Attach the pump to the vacuum chamber valve with the hose. Once attached, simply pull the pump up to create the vacuum in the chamber. Pump it up and down several times to make the vacuum stronger. If you are creating a vacuum chamber, try cutting a hole in the lid of a canning jar that's just big enough to fit part of a straw. Wrap chewing gum around it to hold it in place, then attach the tubing of the bicycle pump to the straw.

Comments

0 comment