views

Preparing the Space

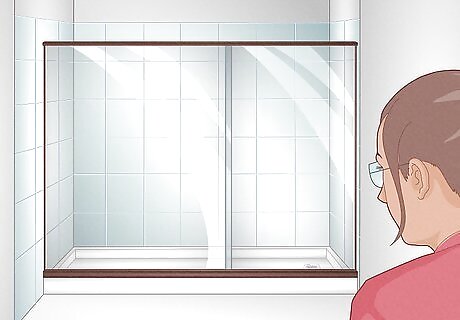

Choose the best shower kit for your space. Many showers installed are prefabricated units, making installation an easy do-it-yourself project for homeowners with basic carpentry and plumbing skills. Shower stall kits come in three basic types that can be installed as either direct-to-studs or glued in place. Alcove shower kits: These are the most common shower kits. They come in square or rectangular shapes and require the support of three walls. They may also be classified as a multi-panel unit. Corner shower kits: This kit is ideal for smaller bathrooms and fit into the corner of the room, requiring the use of only two walls. Corner shower kits can be square, rectangular, or neo-angle with a diagonal or rounded sliding door. Free standing shower kits: These require a single wall for installation, and are also known as single unit stalls, that can be fitted to virtually any area of the bathroom, giving homeowners more flexibility with their layout.

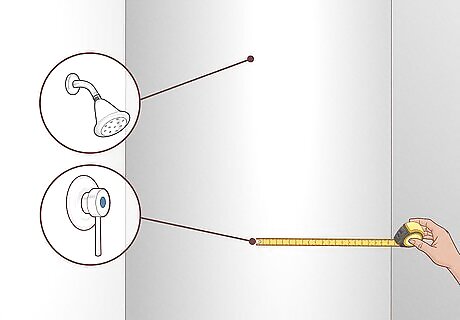

Mark the measurements for your shower control and valves. With a marking pen or pencil, measure from the floor and the corner of the walls to accurately measure any plumbing, valves, or fixtures. Transfer these measurements to the back of the unit, where it will be mounted over these plumbing fixtures. For example, from the corner of the wall to the center of the water control valve might be 18 inches (45.7 cm). From the floor to the center of the valve is 36 inches (91.4 cm). Repeat this for all fixtures that will poke through the stall surface. If you’re installing recessed lighting, measure from all sides of the shower to ensure the light fixture is centered.

Sweep the floors and walls to clear all loose debris. Use a broom or a vacuum to clear construction debris and dust from the area before installing. Use a paint scraper or a putty knife to peel off old caulking and adhesive, and make sure that you thoroughly dry out the area before installing the pan on the subfloor. If your subfloor is wet before you install the panels or the shower pan, you'll risk wood rot and other serious problems in the future.

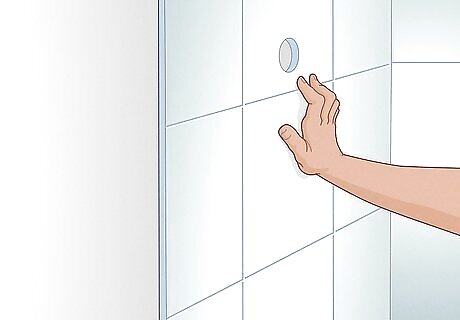

Waterproof the walls. Use waterproof wallboards, prefabricated foam components, or a liquid-applied membrane to waterproof the shower walls before installation. You can also use shower boards that can be attached to the walls with nails or screws. Be sure to seal the seams with silicone waterproof caulking. Never install a shower over regular drywall, as any moisture will eventually disintegrate the drywall.

Installing the Shower Pan

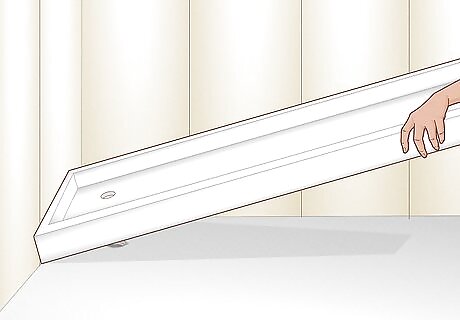

Set the shower pan in position on the floor. Line up the drain hole in the bottom of the shower pan with the drain in the floor. Don't use any adhesives or fasteners; just fit it in and make sure the pan fits snugly within the space. Once in place, check all four corners and ensure they are leveled to the ground. Your shower kit will include a shower pan. However, they’re available in different materials such as fiberglass, acrylic, or in different textures such as tile, pebble, or travertine.

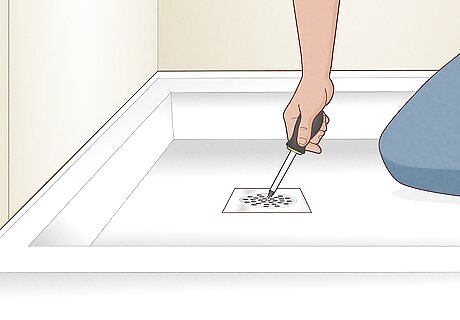

Screw the drain cover down into the shower pan. Some kits may recommend attaching a short coupling piece to the bottom of the drain to attach the pan. If so, slip this into the drain pipe in the subfloor and use a compression gasket (included in your shower kit) to complete the seal.

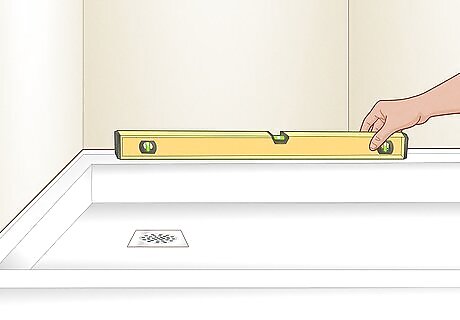

Use a level to ensure the pan aligns with the walls and floor. Use a carpenter’s level to test all four sides of the pan, ensuring the air bubble falls between the two level lines. Use wood shims to level out the pan if you need to adjust the height. Once the pan is in place, mark the top of its lip where it meets the studs and shim placement, just in case you need to readjust things later on. Your shower may leak or overflow if your pan isn’t aligned correctly.

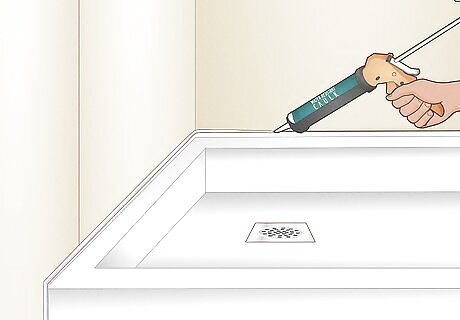

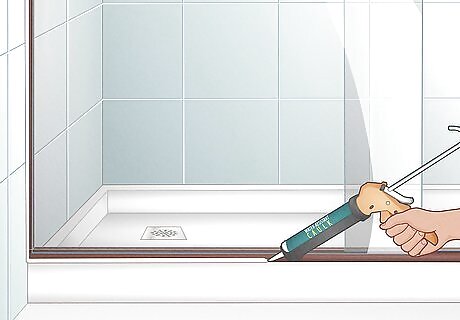

Seal the pan with a thin line of caulk. Draw a bead of caulk along the joint where the pan meets the floor, no thinner than ¼-inch. Use just enough to coat and seal where nails or screws are used to attach the pan to the studs. You can wipe up accidental drips of caulk from the pan before they dry. If you discover them after they dry, use your fingernail or a plastic putty knife to remove excess caulk.

Securing the Shower Panels

Mark each panel according to the kit instructions. Identify each wall panel per the instruction sheet in the shower kit. If they’re not already pre-labeled, use a piece of masking tape and write out “Panel A” or “Panel 1” on the corresponding panel.

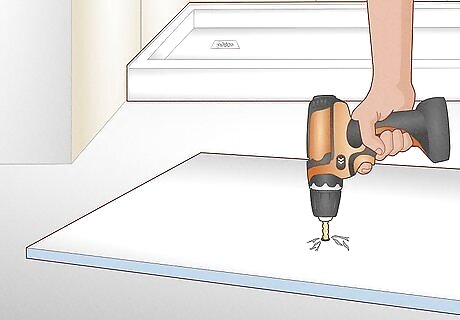

Drill pilot holes on the unit. Use the measurements you gathered previously for the shower controls, fixtures, and valves to cut pilot holes with a 1/8th drill bit. Go slowly and carefully so you don't crack the interior finish. It's important to drill pilot holes from the back of the stall to the front. This will make it easier when you use the saw to cut larger holes for the fixtures. You can also draw a tough sketch of the wall with the plumbing and properly indicate those measurements on the sketch.

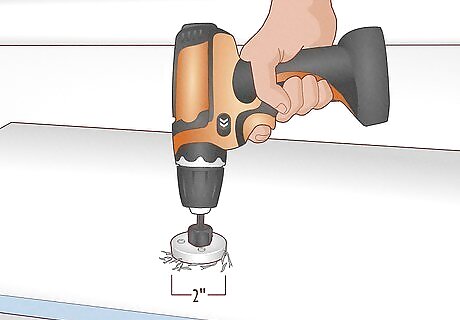

Attach a 2-inch hole saw to your electric drill and cut a hole. Start from inside the shower stall and put very little pressure against the surface while the hole saw it cutting through. Once the saw has cut nearly all the way through, ease up on the pressure until the hole is complete. You may see smoke or smell burning as you cut through the material; this is caused by friction. After a minute or two, the material will cool down. Remove the cutout piece from the hole saw.

Dry-fit each panel in the space. For some kits, the wall panels may need to be installed in a particular order to ensure the seals are flush. Dry-fitting allows you to accurately determine the space and sizing measurements of your shower before installation. Simply take each panel and rest it against the corresponding wall. This is especially important for ensuring each piece is leveled before installation.

Fit the panels' bottom edge into the pan grooves. Shower pans are manufactured with a grooved or slightly offset lip around the pan where it meets the wall. You’ll slide or snap them together or join them with a vertical cap piece or a molded vertical soap dish that overlaps between two panels. These may also be called “exact fit” or “Variable fit” panels. Refer to your kit's instructions for installation guidance.

Install each panel in the appropriate order using a silicone adhesive. Create the shape of an “X” from corner to corner on the back of the panel with a 100% silicone adhesive. Make another bead shaped like a “+” through the middle of the X you just made. Bead along the entire perimeter of the panel, about 2 inches (5.1 cm) in from the edges of the panels to prevent any excess from oozing out. Be sure the panels are completely clean and dry. Apply some adhesive to the shower pan where the panel will make contact. Be sure to squeeze a continuous bead along the pan lip so it forms a watertight seal.

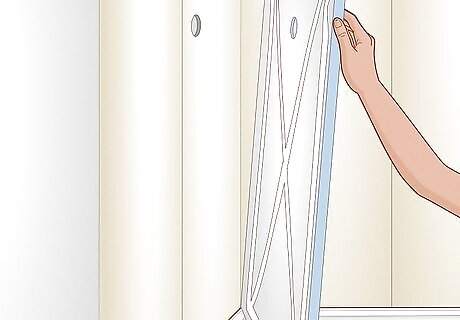

Carefully press the panel into place against the wall. When fitting the panel to the wall, align the corner side first and work your way out, applying even pressure with your hands. Repeat this process with each panel. Remove any excess adhesive that has oozed out from pressing the panels in place before the adhesive can dry. Use the recommended solvent or water noted in the adhesive tube's “cleanup” portion. After several hours, caulk all seams and joints for a watertight seal.

Use wall screws to secure the panels, if necessary. Pre-drill holes for the wall screws or nails on the outer edge of the panels. Then, simply screw or nail your wall screws through the hole to attach them. Do not completely tighten or pound the nails in all the way until each panel is in place so you can adjust if necessary.

Attach the final shower components. Your kit may include molded corner or seam tower pieces, like a molded soap dish or shelf towers. If so, apply a generous amount of 100% silicone adhesive to the back lips of these accessories. Allow the dishes to sit for 24 hours before adding products and other bathroom necessities.

Installing the Shower Door

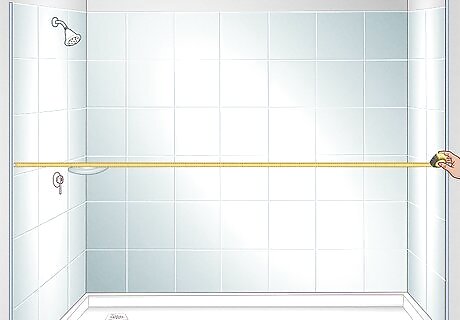

Measure the width of the shower opening. If you’re installing shower doors on a tub, measure where you want the threshold track placed on the front lip of the tub. Be sure to take the full width of the lip and tub to mark the center point. For stand-up showers, the track may just slide into place or lock into the shower pan. Always defer to the instructions included in your specific kit.

Mount the bottom threshold track. Run a bead of caulk along the bottom of the dry mounting surface. Center the bead between the two lines you marked on the tub or pan and run it the full length of the opening. Firmly set the bottom track into place over the bead of caulk. Make sure the underside of the track makes contact with the caulking. If not, run a separate bead along the center of the underside of the track.

Align the wall tracks with the mounting holes on the bottom track. Place the rubber bumpers that come with most door kits over the screws and secure the tracks to the wall. The wall tracks will hold the bottom track in place. Do not completely tighten the screws at this point. Some showers may have no wall tracks for the kit. If there are none, disregard this step and insert the door itself.

Measure and cut the top track, if necessary. Ensure the track fits snugly and is properly aligned between the wall tracks. Many door kits will have corner brackets that are attached with screws to hold the top rail securely. In some shower kits, the track bars are variable sizes, meaning they're sold larger than you may need, and you can cut them to size accordingly. If so, cut the tracks using a hacksaw and file them flush before installing.

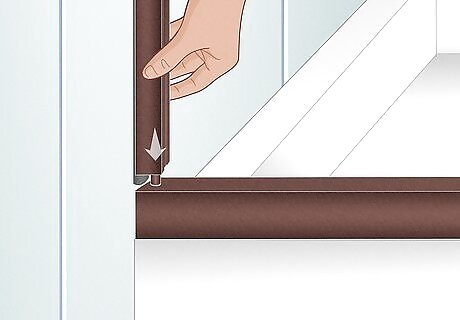

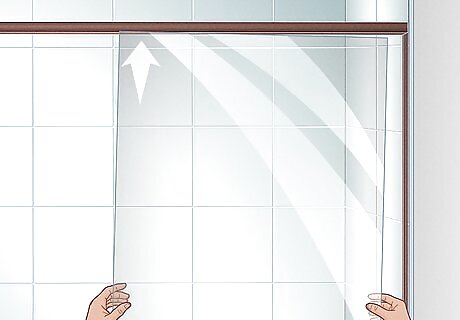

Hang the inside sliding door first. If you're installing sliding doors and both doors have towel bars, mount them with the rollers and the towel bar facing inward. Lift the door into the top rail, then carefully fit the top and bottom rollers into the upper and lower tracks. The door should glide easily from end to end if seated properly. If not, carefully retry until properly seated. Some doors need to have the rollers installed before popping the door into the place. If so, most of them will just pop right into place. Read the instructions.

Install the outer door by aligning it with the top rail. With the towel bar facing outward, install the outer door using the same method as the inner door. Carefully align and seat the rollers into the appropriate tracks. It should slide freely over the inner door if seated properly.

Seal the seams with water-resistant caulk. Run a bead of bathtub caulk along all surfaces where they come in contact with the door tracks. Do this to the inside and outside surfaces, creating a neat, watertight seal. Let the caulk dry for at least 24 hours before running water in the shower to test your job.

Comments

0 comment