views

- Low or inconsistent fuel pressure is a common cause of engine misfires. Test your fuel system to determine if this is affecting your vehicle.

- A broken vacuum line is another common culprit for engine misfires. Look around the engine bay for any severed or damaged rubber lines that need sealing.

- A spark plug that looks black or carbon fouled at the end means the engine was running rich (too much fuel) and may be the cause of your misfire.

- Fixing a misfire can be dangerous or require in-depth repairs, so you might need a pro. Still, if you identify the issue before going into the shop, you'll save money.

Identifying an Engine Misfire

Look for a flashing check engine light. The check engine light on your vehicle’s dashboard will tell you when the computer identifies an engine operation issue. While you usually need an OBDII scanner to read the error codes that prompt a check engine light, a misfire is the only thing that will make the light flash on and off. The check engine light will flash as the engine misfires, but it may also stop if the misfire stops. If your check engine light is not flashing, but you see other signs of a misfire, the engine may still be misfiring.

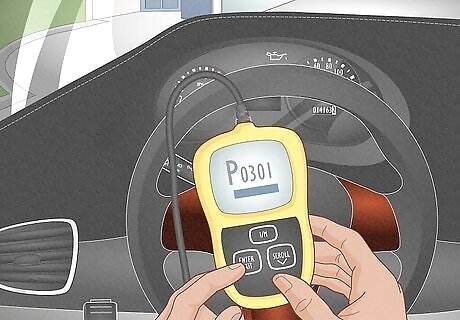

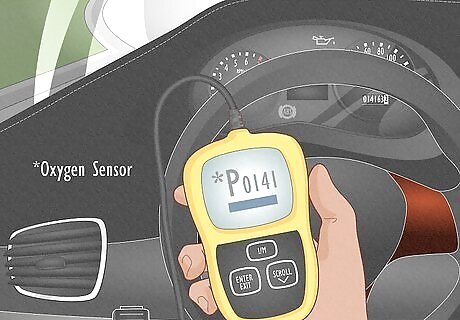

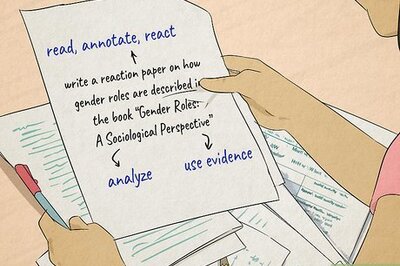

Scan the engine’s error codes. Once you’re confident your vehicle has a misfire, try plugging an OBDII code scanner into the port beneath the dashboard on the driver’s side. It will look like an open trapezoid-shaped plug with rounded edges. Turn the key to the accessories setting on the ignition and turn on the scanner to read the engine’s error codes. The scanner will give you a code that’s made up of numbers and letters. If it doesn’t provide an English description, you can find them in a vehicle-specific repair manual or on the manufacturer’s website. The scanner will give you an error specific to a cylinder misfiring or a generic misfire error across all cylinders.

Feel for a strong vibration from the engine bay. Engines are designed to be balanced as they run, so the engine’s balance will be thrown off if a cylinder stops firing. During a misfire, the engine will begin to shake violently, and often, that shaking will translate to vibrations throughout the rest of the car. Misfires don’t always happen consistently, so the vibration may come and go under different driving conditions. If it feels like the engine is misfiring, note what kind of driving you were doing at the time (sitting at a stoplight, driving on the highway, etc.).

Listen for sputtering. A bad misfire can sound a lot like your vehicle is going to stall, and in some cases, it may. Sputtering sounds coming from the engine or the exhaust pipe of your car is a solid indication that 1 of the cylinders is misfiring. Sputtering alone can mean other issues aside from a misfire, including a loss of fuel or airflow into the engine, so look for these signs of a misfire as well.

Check to see if your fuel mileage is getting worse. If a cylinder in your engine isn’t working, it may run unspent fuel through the exhaust. That not only means a loss of power but also reduced fuel economy. If you’ve noticed that your vehicle’s gas mileage has suddenly gotten much worse, it’s likely a sign of a misfire. Reset the trip odometer on your dashboard when you fill up your gas tank to see how many miles you make before you need another fill-up. Divide that number by the number of gallons you put in to get your mileage. Compare your calculated mileage to your vehicle’s mileage rating in the owner’s manual if you’re unsure what it typically is.

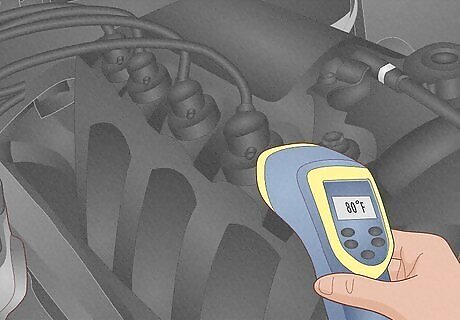

Check cylinder temperatures with an infrared temperature meter. If scanning the error codes didn’t help you identify which cylinder is misfiring, you can also check by using an infrared thermometer to see cylinder temperatures. Your engine's exhaust manifold(s) will have a port coming from each cylinder. Point the temperature meter at each individually with the engine running and write down the temperature readings. If 1 cylinder is not firing, it will be much cooler than the others. This test has a wide range of acceptable temperature readings, so what matters most is identifying the cylinder that stands out as not as hot as the others. For instance, if 3 cylinders read 190 °F (88 °C) and 1 shows as 80 °F (27 °C), the low one is the issue. This will only work while the engine is misfiring. If your misfire comes and goes, make sure to do this test while it’s happening.

Fixing Air and Fuel Misfires

Use unrelated error codes to help narrow down the cause. When you use a code scanner to see if there are any cylinder-specific error codes, you might also see some others pop up. These may not relate to the misfire, but some certainly could. Suppose an error code appears regarding fuel delivery (injectors, pump), the mass air flow sensor, or the oxygen sensor. In that case, those may be from issues that are causing the misfire. If the misfire is not specific to 1 cylinder, it’s likely because the engine is not getting enough air or fuel to run properly. That could be because of a failing part of the fuel system. If the mass air flow or oxygen sensor fails, it could give incorrect data to the engine’s computer, causing a misfire. Take note of any error codes that pop up to help you as you move forward in diagnosing the problem.

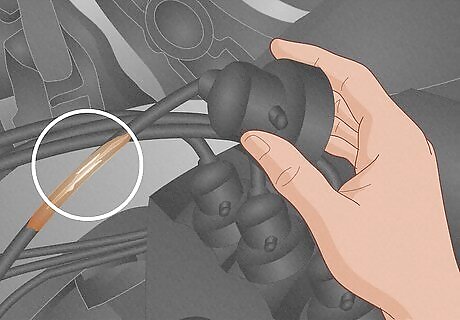

Find and seal any vacuum leaks. A broken vacuum line can cause fuel-injected motors to misfire, so look around the engine bay for any severed or damaged rubber lines coming from the engine’s intake manifold (usually near the top of the engine with the intake leading into it). Replacing a bad vacuum line may resolve the misfire or help the engine run better.

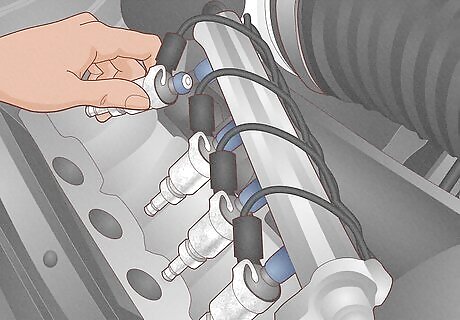

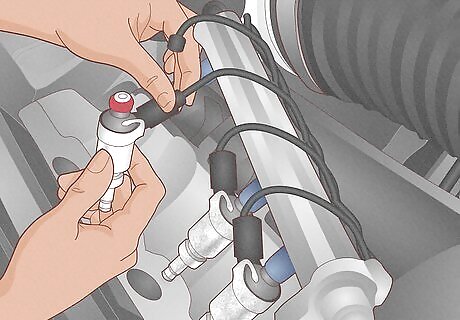

Disconnect the fuel injectors one at a time and look for a change. If you’re still having trouble finding the misfiring cylinder, disconnect the power to the fuel injectors one at a time to see its effect on the engine. Locate the connector where it attaches to the back of the fuel injector. If you need help locating the fuel injectors, consult your repair manual to help you find them. If the engine starts to run worse with 1 injector disconnected, reconnect it and move on to the next. If you disconnect a fuel injector and the engine’s behavior doesn’t change, the cylinder isn’t firing and is the source of your issue.

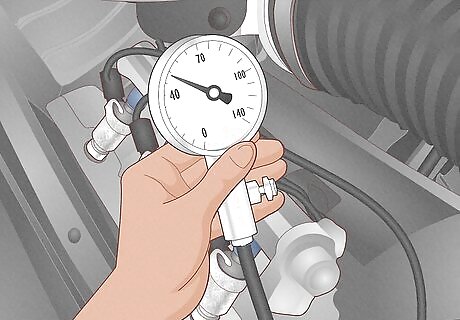

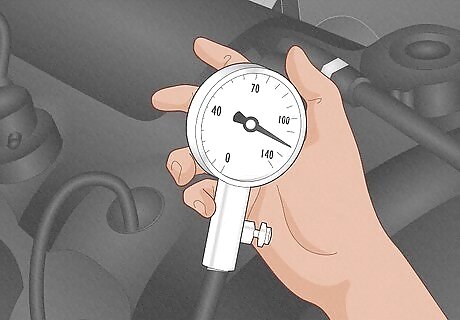

Test your fuel system if the injectors seem fine. Attach a fuel pressure gauge to the fuel pump test fitting at the end of the fuel rail on the engine. Find the appropriate pressure specifications for your vehicle in its repair manual and then compare it to the readings you get when the engine running at an idle and then at the RPMs specified in the repair manual. If the fuel pressure is low or inconsistent, the fuel system prior to the fuel rail is causing the misfire. If this is the case, you’ll need to either replace the fuel filter or the fuel pump. Replacing the fuel pump might require removing it from the fuel tank, so assistance from a professional mechanic may be necessary.

Replace the fuel injector if it's not working. Connect a test light to the negative terminal of the vehicle’s battery, then press the probe into the wire leading into each fuel injector. If the test light comes on, power is flowing to each injector. If not, there’s an electrical issue somewhere that will need a professional technician to address. If you got an error code specific to your fuel injector, replacing it should solve the problem. You may be able to clean your fuel injectors instead of replacing them by pouring fuel system cleaner in with a full tank of gas.

Replace the mass air flow or oxygen sensors if they have errors. If your code scanner indicated that there were problems with the mass air flow sensor or oxygen sensor, they might be the cause of your misfire. The mass air flow sensor is located on the intake pipe, usually just past the air filter. Oxygen sensors, on the other hand, are found on the vehicle’s exhaust, usually before the catalytic converter. Remove the mass air flow sensor by removing the two screws that hold it in place on the vehicle’s intake and disconnecting the wiring pigtail that leads into it. You can remove the oxygen sensor by disconnecting the wires and unscrewing it with an oxygen sensor socket. Make sure to connect the new sensors using the wires you unplugged from the old ones, then secure them in place using the same mounting hardware.

Addressing Electrical or Mechanical Misfires

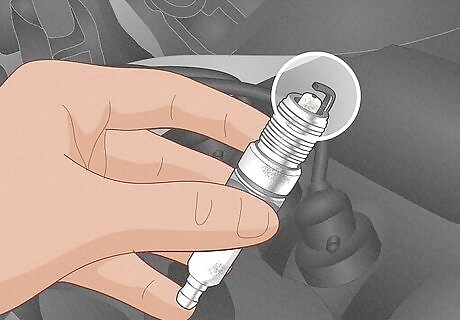

Inspect the spark plugs for signs of damage. Once you’ve determined which cylinder is misfiring, disconnect the plug wire going into that cylinder’s spark plug. Use a spark plug socket to remove the plug to get a good look at it. The damage you see will help you determine the cause of the misfire. If the spark plug is just old, replacing it may solve the problem. Make sure to replace and properly gap new spark plugs. A spark plug that looks black or carbon fouled at the end means the engine was running rich (too much fuel). A plug wet with gasoline or oil means the fuel regulator may have failed or there are serious internal issues inside the engine block. If the plug looks fine, check the gap between the metal sticking out of the end of the plug and the base. Compare that gap to the specified gap in the vehicle’s repair manual. If the gap is too big, it may be preventing the air/fuel mixture from firing. You may also need to replace the wire that delivers the spark from the ignition coil to the spark plug.

Use an Ohmmeter multimeter to test your coil pack. Spark plugs ignite the air and fuel mixture using current transmitted from the coil pack, so a faulty one can result in a misfire. Many vehicles will provide a specific error code if a coil goes bad, but you can test a coil by disconnecting the spark plug wires and connecting an Ohmmeter (multimeter) to the top two pins. Compare the resistance you see on the Ohmmeter’s readout to the resistance for your specific vehicle. If it doesn’t match, the coil pack needs replacing. You can find the correct resistance rating in your vehicle’s repair manual. Find the coil packs by running your hands along the spark plug wires, moving away from the spark plugs. If the coil needs replacing, disconnect the rest of the wiring and unbolt it from the bracket. Insert a new coil and reconnect it like the old one.

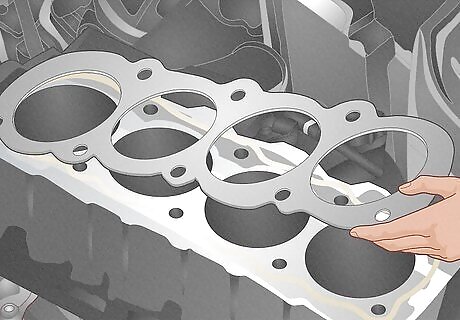

Do a compression test if air, fuel, and spark seem to be in order. Pull out the fuse that powers the fuel pump (use the owner’s manual to locate it if you’re unsure). Then remove 1 of the spark plugs and screw a compression gauge into its place. Turn the key and let the engine turn over four times, then check the reading on the gauge. It will stay at the highest point it reached. Repeat this process for each cylinder. Make sure to reinsert the spark plugs after you remove the gauge every time. Like the temperature test, all cylinders should have similar figures except 1, if a lack of compression is causing the misfire. If the numbers are the same across the board, the misfire is not compression related. If numbers are low across two cylinders near each other, it likely means the head gasket is bad in that area. You will need to remove the cylinder head from the engine to replace the head gasket.

Replace the head gasket if nearby cylinders don’t have compression. If the misfire is happening in two cylinders near each other, it’s probably caused by a blown head gasket. Other signs of a blown head gasket include finding coolant in your oil (bright green or pink translucent fluid), bluish exhaust smoke color, and an oil leak where the cylinder head (top half) of the engine meets the block (bottom end). Replacing a head gasket is a pretty involved job that requires specialized tools in many applications. If you believe your cylinder head gasket has failed, take the vehicle to a certified repair technician.

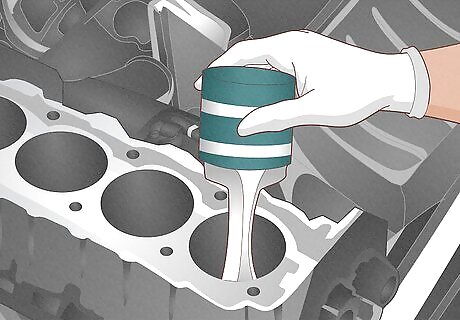

Have the engine rebuilt if there’s a serious lack of compression. In extreme cases, an engine misfire can be caused by failed piston rings or even damaged cylinders or connecting rods. If your spark plug is covered in oil, it might have be because the piston rings have failed, allowing the oil to move freely past the cylinder and eliminating compression in that cylinder. If this is the case, the crankshaft, connecting rods, and cylinders will need to be removed from the engine to replace the damaged components. Rebuilding the bottom end of an engine is a complicated and difficult process best left to professionals.

Comments

0 comment