views

Make sure the gas bottle is empty. Often you will know the forklift gas bottle is empty when the forklift's engine slowly dies out and shuts off / stops working. However, a common mistake is to start with the gas valve turned off; this will often let the forklift run for a few minutes before the engine suddenly stops, giving you a false impression that the forklift has run out of gas, when in fact the valve is simply turned off. An empty gas bottle is not necessarily checked by the fact the gauge reads "empty", as this gauge is often inaccurate and will not correctly measure the amount of fuel left in the bottle (e.g. a gauge reading "empty" may still be driven for up to 30 minutes or more!). To know if the gas is actually empty, note whether the engine dying out and stopping when the valve is ON and everything is connected, and, once disconnected, the empty gas bottle will be extremely light on its own. A full bottle will usually weigh almost twice as much as an empty one.

Wear PPE. Although in many countries and companies, this is not enforced at all by legal, work safety, or company policy, it is highly recommended to wear the Personal Protective Equipment (PPE) consisting of glasses and gloves, as a minimum, when changing the gas bottles on gas powered forklifts. Even when everything is done correctly, faulty seals, faulty gas bottles, and other factors can contribute to significant "gas leaks" when removing or replacing the gas bottle to the forklift. Even when the valve is closed, gas can still violently "spray out" and cause significant cold burns or even blindness. In any case, caution is always preferable when removing or replacing the forklift gas bottle.

Turn off the gas valve and disconnect the gas bottle from the forklift's gas connection hose. Once you are ready to change the bottle, ensure the forklift is in neutral with the forks flat on the ground to avoid trips and the handbrake applied, turn off the gas valve and slowly unscrew the gas bottle from the forklift's gas hose, thus disconnecting the gas bottle connection from the forklift.

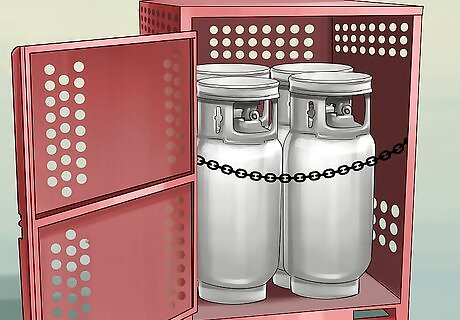

Undo any strapping/gas bottle securing latches and put away the gas bottle. Depending on the forklift model, this may be a simple snap latch system, or it may be a custom built strapping system. Ask for assistance if you are unsure. Similarly on any worksite, you will need to ask your supervisor/other co-worker where the empty forklift's gas bottles are kept. Some workplaces will have a separate cage or area for them; others will have the empty bottles turned upside down with the other bottles.

Get a new bottle, re-strap, reconnect, turn on and start! Once you have your new/full gas bottle, you can replace it back on to the forklift. As full gas bottles are almost twice as heavy as empty bottles, you may want to ask a passing by co-worker to assist you lifting the gas bottle onto the forklift. Re-strap the bottle, and always ensure it is turned OFF before reconnecting the forklift gas hose to the bottle. If the gas bottle does happen to be turned on while you are connecting it, this is certain to cause a spray of gas/gas leak leading to possible cold burns! As previously mentioned, even then the gas bottle's valve is Off, a small amount of gas can still leak out when being disconnected and reconnected - when reconnecting, a small amount of leak initially when connecting/screwing in the bottle to the forklift's gas hose is normal so long as the leak stops once the gas bottle is fully connected.

Start the forklift. Once the forklift has been properly reconnected (make sure it's moderately tight, and not cross threaded), you may turn the gas on and start the forklift. The forklift should start within seconds; you can "rev" the forklift to be sure the gas has been correctly changed. Now the forklift driving begins!

Comments

0 comment