views

Preparing the Flame

Put on a pair of safety goggles before you handle the torch. Wearing safety goggles is a necessary precaution to ensure eye safety anytime you are working with open flames. Wear a pair of goggles that are rated to at least shade 4 to adequately block the bright acetylene flame from harming your eyes. If you don't wear safety goggles, you could risk seriously damaging your eyes by looking directly at the acetylene flame. Goggles used for annealing, arc cutting, and welding are rated on a scale of 2–14, with 2 as the least tinted and 14 as the most tinted. Since an acetylene torch is much less bright than a welding torch, your eyes will be protected by relatively lightly tinted glasses. If you do not own a pair of safety goggles, purchase a pair at a large hardware store or a welding-supply store.

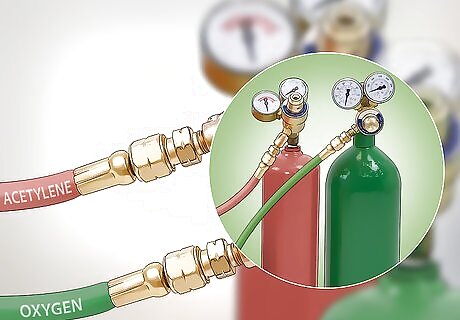

Connect 1 hose to each tank to set up the acetylene torch. The torch itself—which will produce the flame—will have 2 hoses coming out of it. Connect the red welding torch hose to the acetylene tank, and the black hose to the oxygen tank. The acetylene gas will start the flame and the oxygen will continue to feed the flame once it's lit. You'll also adjust the amount of oxygen coming from the tank to control the intensity of the flame. Before you begin, make sure that the 2 pressure gauges on the oxygen tank and the 2 pressure gauges on the acetylene tank are all at “0.” If you don't already have an oxygen acetylene torch, you can purchase or rent one from a large hardware store or a home-improvement store.

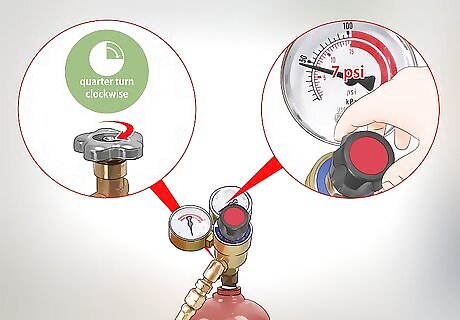

Turn the acetylene valve a quarter turn clockwise. This will engage the gas tank and switch on the flow of acetylene to the regulator. Only turn the valve a quarter of a turn to ensure that there is enough acetylene to start the flame, but not so much that it will be too large to control. Keep an eye on the pressure valve and fine-tune the acetylene valve until it reads 7 psi (pounds per square inch). You'll find the pressure gauge directly on top of the large acetylene tank. Look for the dial that is marked “pressure” or “psi.” Once the flame is burning consistently, you can adjust its intensity by turning the acetylene-tank valve so it's more or less open. Find the tank valve on top of the acetylene tank. In most cases, it will be next to (or even attached to) the pressure gauge.

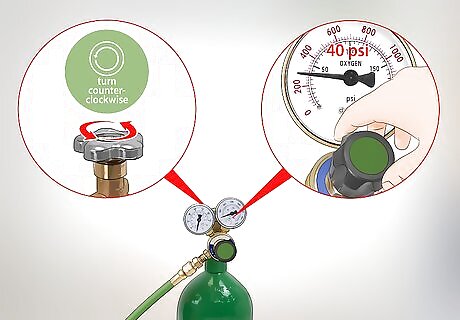

Turn the valve on the oxygen tank as far as it goes counterclockwise. Once the oxygen tank valve is fully on, adjust the line pressure by turning the oxygen tank regulator knob clockwise. Take a look at the regulator gauge on the oxygen tank to make sure that it's at 40 psi. If it's not, fiddle with the regulator knob until the gauge reaches the desired pressure. The oxygen-control valve will be a handle located on the top of the oxygen tank. It may have a directional arrow indicating which way is “on.” A correct mixture of oxygen to acetylene is crucial to produce a hot, manageable flame.

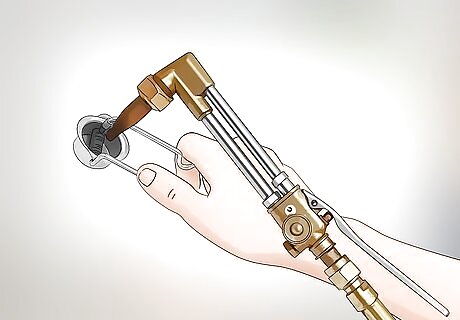

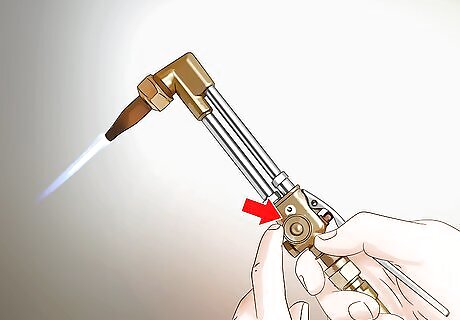

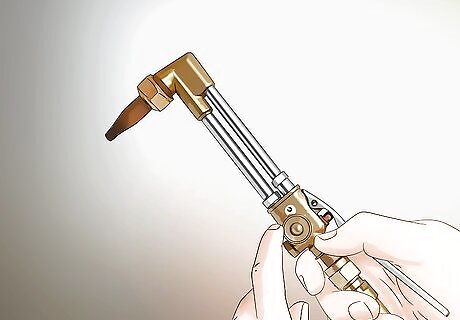

Light the acetylene torch with a flint striker. To light the flame, hold the acetylene torch in 1 hand and turn the acetylene knob (on top of the gas tank) a half-turn clockwise with your other hand. This will start the flow of gas. Hold a flint striker about ⁄2 in (1.3 cm) away from the torch head. Spark it repeatedly until you see an orange-red flame. Once you've turned on the acetylene gas knob, don't wait more than 2–3 seconds to pick up the striker once the gas is flowing, as it's incredibly flammable.

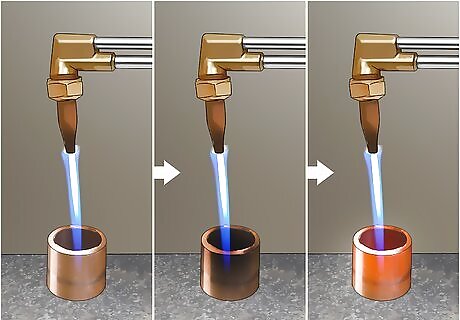

Turn the oxygen valve until the flame turns blue. Once a bright orange flame is coming out of the tip of the torch, turn the oxygen valve on the side of the torch clockwise to introduce oxygen into the burning acetylene. Continue turning the knob until the flame turns blue. A blue-colored flame indicates that the flame is at the ideal temperature for annealing copper. Turn on the flow of oxygen slowly, so the flame doesn't suddenly flare up. A flame that is too hot will burn the copper, while a flame that is too cool will not be strong enough to change the copper's properties like durability and malleability.

Heating the Copper

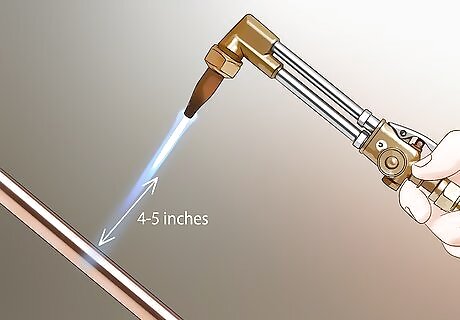

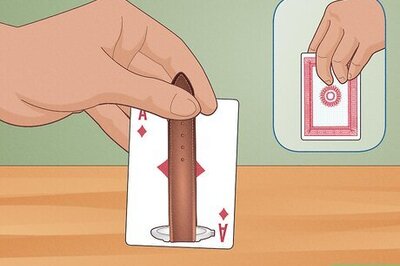

Hold the flame 3–4 in (7.6–10.2 cm) from the copper you're annealing. Point the flame directly at the copper band or pipe. If you hold the flame much closer to the copper, you'll burn the metal's relatively delicate surface. Hold the flame farther than 4–5 inches (10–13 cm) away, and the copper will take a long time to heat. The copper won't catch on fire. However, to avoid catching anything else in your work environment on fire, the copper should be on top of a non-flammable object like a piece of brick or concrete. Always anneal copper in a well-ventilated area. Annealing copper produces chemicals that can harm your lungs if the room you're working in doesn't have proper ventilation.

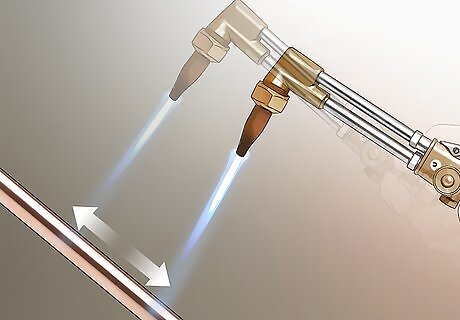

Move the torch quickly back and forth above the surface of the copper. Keep the flame moving across the full surface of the copper to evenly heat it. It's important that you distribute the heat evenly, so no areas of the copper are annealed faster than any others. As you heat the surface of the copper, you'll notice that red and orange colors swirl across the metal's surface. Have a dry chemical fire extinguisher in close proximity whenever you use an open flame. If any of the materials in your garage or metalworking lab catch on fire, spray them with the fire extinguisher immediately.

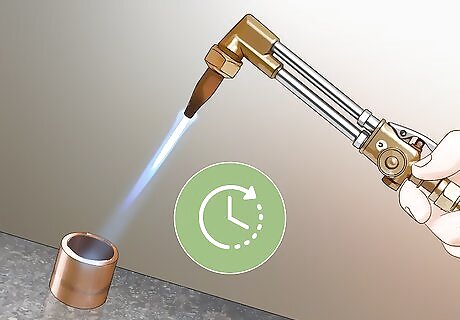

Spend extra time annealing thicker or heavier pieces of copper. The annealing process can work to soften any piece of copper, regardless of its thickness or size. However, the amount time that you'll need to heat the copper for will increase proportionately with the thickness of the copper. For example, you may only need to heat a thin jewelry-grade piece of copper for 20 seconds to anneal it. For a heavy copper pipe or ⁄2 in (1.3 cm) thick chunk of copper, you'll need to anneal for at least 2–3 minutes.

Keep the flame focused on the copper until it turns red. As you continue to heat the surface of the copper with your acetylene torch, it will turn black. Don't worry that you're burning the copper yet; it must turn black before it turns red. Continue moving the torch over the surface of the copper until the black color turns into a bright, glowing red. At this point, the copper is annealed. Regardless of the size or thickness of the copper you're annealing, it will be fully annealed once it's glowing red. Copper that is glowing cherry red is at the correct temperature for annealing purposes.

Cooling and Drying the Copper

Turn the torch valves back to their closed position. Once the copper is annealed, you don't have any more need for the flame. Turn the acetylene valve counterclockwise to shut off the flow of gas. Then turn the oxygen valve back to its closed position as well. Turning the valves back to their closed positions will ensure that the flame is extinguished. At this point, you can remove your safety goggles. Closing the acetylene valve first and the oxygen valve second will clear the torch of any acetylene. Even when you're turning off the acetylene torch, be careful not to point it at any other people in your workspace.

Pick up the annealed copper with a pair of pliers. At this point, the copper will be incredibly hot, so you obviously cannot pick it up with your bare hands. So, slip 1 of the jaws of a pair of pliers under the edge of the copper bar or pipe, squeeze the pliers tightly shut, and pick up the annealed copper. If you don't already have a pair of pliers, purchase a pair at a local hardware store. You don't need to wear gloves at this point (or at any other point during the annealing process), since you'll never touch the metal directly until it's cool. In a pinch, you could use a pair of ordinary tweezers to pick up the superheated copper. Just be careful not to drop it!

Deposit the annealed copper into a metal bucket of water. This will cause the red-hot copper to immediately lose heat and cool off. Keep an eye on the copper so you can gauge its temperature. Once the metal returns to its original reddish-brown color, use the pliers to remove the copper from the metal bucket. The cooling process should take less than 5 minutes. Once this time has passed, the copper is now annealed and will be soft and malleable for working. It's important that you use a metal bucket to cool the heated metal, since it could potentially melt through a plastic bucket.

Comments

0 comment